The DeWALT DW733 Manual provides essential instructions and safety guidelines for the effective use of the DeWALT DW733 12-1/2" Heavy Duty Portable Thickness Planer. This comprehensive manual covers everything from the initial setup and electrical connection to detailed operational controls and regular maintenance procedures. It emphasizes the importance of adhering to safety protocols to avoid injuries and ensure optimal performance. By following the step-by-step instructions provided in the manual, users can maximize the efficiency and longevity of their DeWALT DW733 planer.

Important Safety Instructions (For all tools)

Grounding Instructions

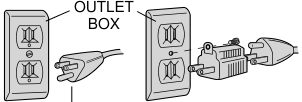

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding conductor and grounding plug. The plug must be plugged into a machine outlet that is properly installed and grounded in accordance with all local codes and ordinances. Do not modify plug provided – if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The conductor with insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in doubt as to whether the tool is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the tool’s plug.

Repair or replace damaged or worn cords immediately.

Grounded, cord-connected tools intended for use on a supply circuit having a nominal rating less than 150 volts: This tool is intended for use on a circuit that has an outlet that looks like the one illustrated in Figure A. The tool has a grounding plug that looks like the plug illustrated in Figure A. A temporary adapter, which looks like the adapter illustrated in Figures B and C, may be used to connect this plug to a 2-pole receptacle as shown in Figure B if a properly grounded outlet is not available. The temporary adapter should be used only until a properly grounded outlet can be installed by a qualified electrician. The green-colored rigid ear, lug, and the like, extending from the adapter must be connected to a permanent ground such as a properly grounded outlet box.

Grounded, cord-connected tools intended for use on a supply circuit having a nominal rating between 150 – 200 volts, inclusive: This tool is intended for use on a circuit that has an outlet that looks like the one illustrated in Figure D. The tool has a grounding plug that looks like the plug illustrated in Figure D. Make sure the tool is connected to an outlet having the same configuration as the plug. No adapter is available or should be used with this tool. If the tool must be reconnected for use on a different type of electric circuit, the reconnection should be made by qualified service personnel; and after reconnection, the tool should comply with all local codes and ordinances.

Permanently connected tools: This tool should be connected to a grounding metal permanent wiring system; or to a system having an equipment-grounding conductor.

Important Safety Instructions

- KEEP GUARDS IN PLACE and in working order.

- REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys and adjusting wrenches are removed from tool before turning it on.

- KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

- DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet locations, or expose them to rain. Keep work area well lighted.

- KEEP CHILDREN AWAY. All visitors should be kept safe distance from work area.

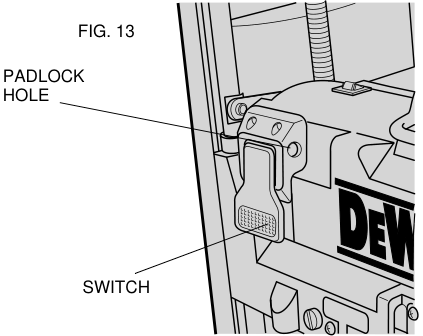

- MAKE WORKSHOP KID PROOF with padlocks, master switches, or by removing starter keys.

- DON’T FORCE TOOL. It will do the job better and safer at the rate for which it was designed.

- USE RIGHT TOOL. Don’t force tool or attachment to do a job for which it was not designed.

- USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The following table shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage number, the heavier the cord.

| Volts | Cord Length (in Feet) | Wire Gauge (AWG) |

|---|---|---|

| 120V | 0-25 | 16 |

| 26-50 | 16 | |

| 51-100 | 14 | |

| 101-150 | 12 | |

| 240V | 0-50 | 16 |

| 51-100 | 14 | |

| 101-200 | 12 | |

| 201-300 | Not Recommended | |

- USE PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry which may get caught in moving parts. Nonslip footwear is recommended. Wear protective hair covering to contain long hair.

- ALWAYS USE SAFETY GLASSES. Also use face or dust mask if cutting operation is dusty. Everyday eyeglasses only have impact resistant lenses, they are not safety glasses.

- SECURE WORK. Use clamps or a vise to hold work when practical. It’s safer than using your hand and frees both hands to operate tool.

- DON’T OVERREACH. Keep proper footing and balance at all times.

- MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest performance. Follow instructions for lubricating and changing accessories.

- DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits, cutters, and the like.

- REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in off position before plugging in.

- USE RECOMMENDED ACCESSORIES. Consult the instruction manual for recommended accessories. The use of improper accessories may cause risk of injury to persons.

- NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is unintentionally contacted.

- CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should be carefully checked to determine that it will operate properly and perform its intended function – check for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced.

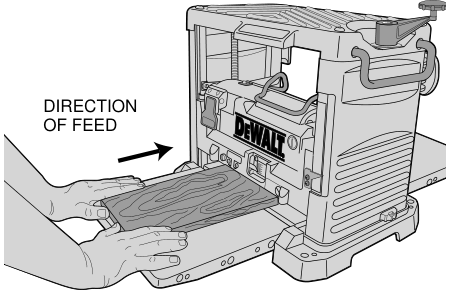

- DIRECTION OF FEED. Feed work into a blade or cutter against the direction of rotation of the blade or cutter only.

- NEVER LEAVE TOOL RUNNING UNATTENDED. Turn power off. Don’t leave tool until it comes to a complete stop.

Additional Safety Rules for Planers

- To reduce the risk of injury, user must read and understand instruction manual before operating planer.

- Always wear eye protection and dust mask if necessary.

- Keep hands 6″ away from motor carriage when feeding work piece.

- Never make cutter knife replacement or any other repairs/adjustments with unit plugged in.

- Make certain that the switch is in the off position before connecting plug to power source.

- Be sure that the cutter knives are mounted as described in the instruction manual and check that all bolts are firmly tightened before connecting unit to power source.

- To avoid injury, never rotate the cutter block directly with your hands.

- Keep guards in place and in good working order.

- Stay alert – never operate the unit when tired or under the influence of drugs, alcohol, or medication.

- Do not use in dangerous environments. Do not use near flammable substances, in damp or wet locations, or expose to rain.

- Never plane material which is shorter than 12 inches.

- Do not wear gloves, neckties, jewelry, or loose clothing.

- Some wood contains preservatives such as copper chromium arsenate (CCA) which can be toxic. When planning these materials extra care should be taken to avoid inhalation or minimize skin contact.

- Exhaust chute: remove shavings with brush or vacuum after power has been shut off and cutter head has stopped rotating.

- ALWAYS LOCATE PLANER WITH PROPER CLEARANCE ON THE OUTFEED SIDE of the unit to prevent pinching or binding of the workpiece or any other obstacle.

- lead from lead-based paints,

- crystalline silica from bricks and cement and other masonry products, and

- arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well-ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

Specifications

- Motor: 120V AC, 15 Amp

- No-load speed: 10,000 RPM

- Feed speed: .26 ft. per minute

- Planing height: Maximum 6”, Minimum 1/8”

- Planing width: Maximum 12-1/2”

- Planing depth: Maximum 1/8” (for boards 5 1/2” wide or less)

Electrical Connection

Be sure your power supply agrees with the nameplate marking. All DeWALT tools are factory tested; if this tool does not operate, check the power supply.

Familiarization

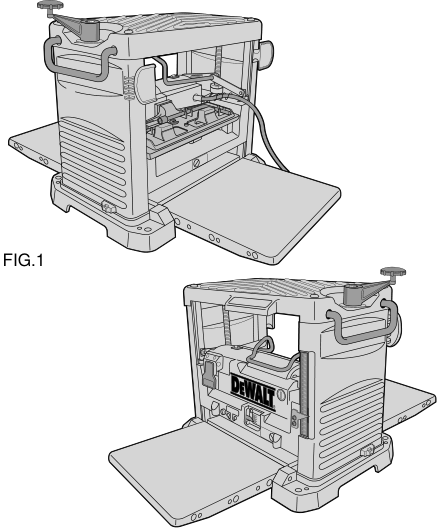

Except for the depth adjustment handle, our planer is fully assembled when you receive it. See Figure 1.

Unpacking Your Planer

Check the contents of your planer carton to make sure that you have received all parts. In addition to this instruction manual, the carton should contain:

- 1 allen wrench

- 1 L-shaped both wrench

- 1 open-ended wrench (10mm/8mm)

- 2 magnetic knife gauges

- 1 depth adjustment handle

- 1 Allen screw

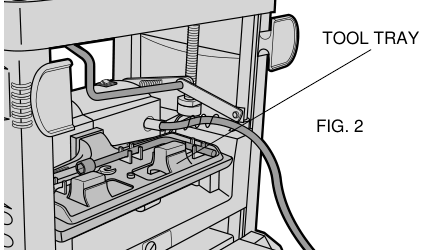

These tools are located in the tray on the back side of your planer, as shown in Figure 2.

Attaching Depth Adjustment Handle

Using the allen screw provided, attach the depth adjustment handle as shown in figure 9.

Bench Mounting

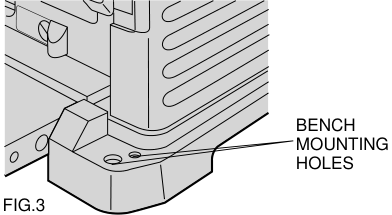

Attach your planer to the four corners of your planer to facilitate bench mounting, as shown in Figure 3. (Two different sized holes are provided. If mounting the planer with bolts, use the larger holes. If mounting with nails or screws, use the smaller holes. Use either size hole; it is not necessary to use both.) Always mount your planer firmly to prevent movement. To enhance the tool’s portability, it can be mounted to a piece of 1/2” (12.7mm) or thicker plywood which can then be clamped to your work surface

Transporting the Planer

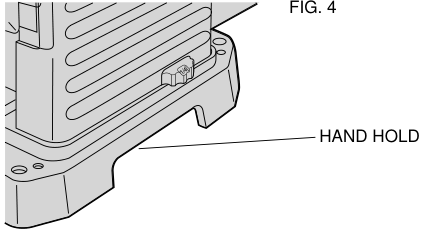

When moving your planer, carry it either by the side carrying handles or by the hand indentation at the base of the planer. (Figure 4).

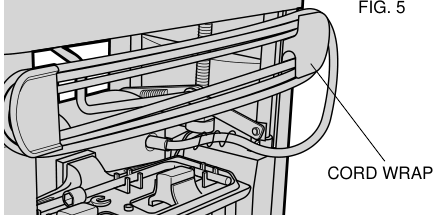

When transporting or storing the planer, use the cord wrap located in the back of the tool. (Figure 5) to keep the cord in place.

Operating Controls

Table Extensions

Before using your planer, fold down the table extensions in the front and back of the tool. The back edge of each table extension is adjusted to be level with main table

Depth Adjustment

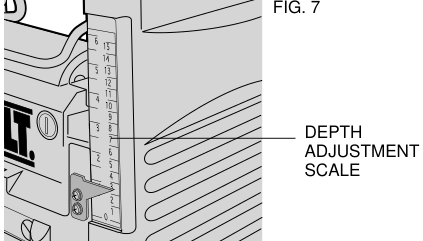

DEPTH ADJUSTMENT SCALE

The depth adjustment scale, located on the right front of your planer, indicates the finished thickness of your workpiece

DEPTH ADJUSTMENT HANDLE

To set the finished thickness, first unlock the head lock lever

Turning the handle clockwise lowers the cutting head, while turning counter-clockwise raises the cutting head. One full rotation of the handle moves the cutter head 1/16”.

FINE ADJUSTMENTS

The depth adjustment handle also allows for fine adjustments, from 1/64” to 1/16”.

Note: For best results, make several passes, planing both sides of the workpiece

On/Off Switch

To turn the planer on, flip up the switch, as shown in

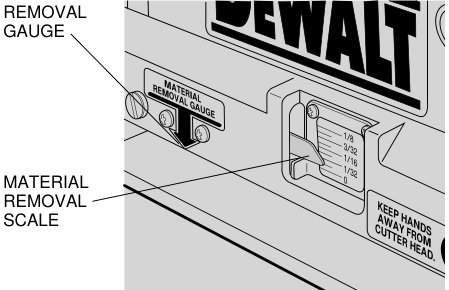

Material Removal Scale

Your planer is equipped with a material removal scale, which indicates the amount of wood being removed in a single pass/pattern

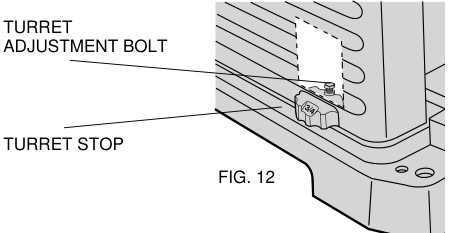

Turret Stop

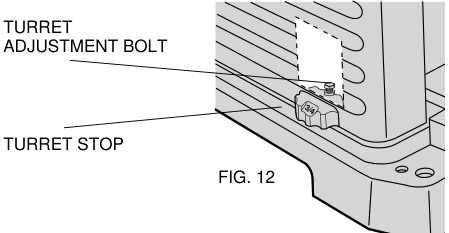

Your planer is equipped with a turret stop

Warping

Warped wood can not only jam the planer, it can produce variations in the final thickness of the workpiece.

Planing

After making all adjustments, turn the tool on and wait until the knives reach full speed. The workpiece should not be in contact with the feed rollers or the cutterhead when the tool is switched on.

Feed wood into the planer as shown in Figure 14. Do not force wood into the cutterhead. Let the feed rollers determine how fast the wood is planed.

Adjustments

Changing Knives

Removing Knives

- Turn off and unplug planer. Lift the headlock lever to the up, or unlocked position.

- Adjust the depth of cut until the scale reads about 3”. This will ensure ample room to change the knives.

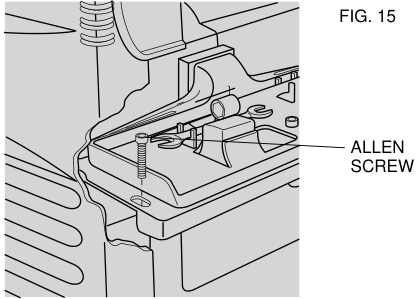

- Remove the two allen screws near the tool tray, shown in (Figure 15). Carefully lift off the dust chute.

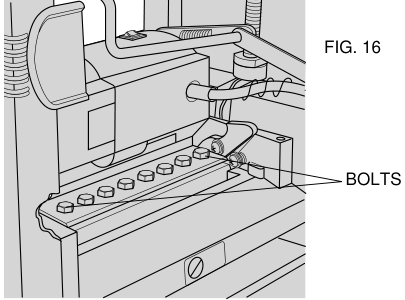

- If the eight bolts shown in (Figure 16) are not visible, rotate the cutterhead using a small piece of scrap wood.

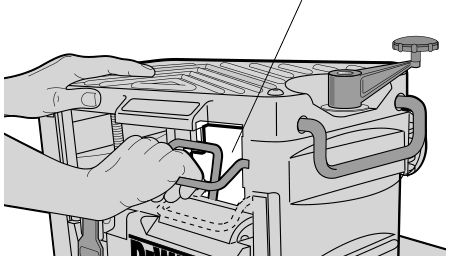

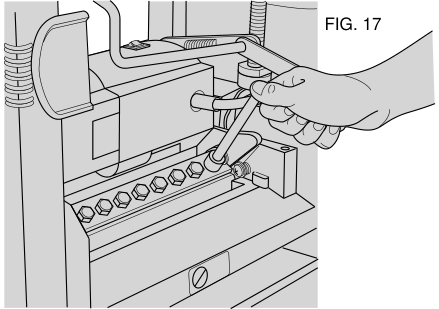

- Using the supplied L-shaped wrench, loosen, but do not remove, the two end bolts shown in (Figure 17).

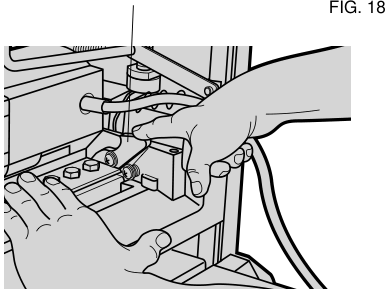

- Press the cutterhead lock lever (Figure 18) down toward the knife and gently roll the cutterhead backward until the knife can be removed.

- Press the cutterhead lock lever (Figure 18) down and roll the cutterhead until the other knife assembly is visible. Remove this knife following the steps above.

REPLACING KNIVES

- Position the cutterhead as shown in (Figure 19).

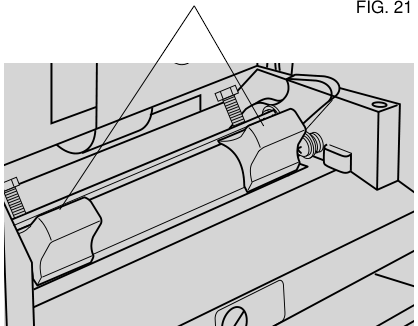

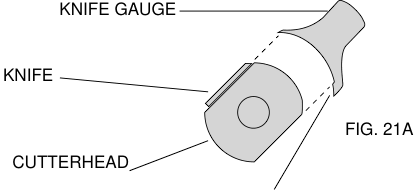

Knife gauges - Carefully slide the new knife onto the cutterhead, as shown in (Figure 20). Place the two magnetic knife gauges (located in the tool tray) onto the cutterhead as shown in (Figure 21). Ensure the flat edge of the knife gauge is in contact with the flat edge of the cutterhead

Knife and knife gauge (Figure 21A).

Knife placement - Firmly tighten the two end bolts, using the open-ended wrench provided, as shown in .

Tightening the bolts

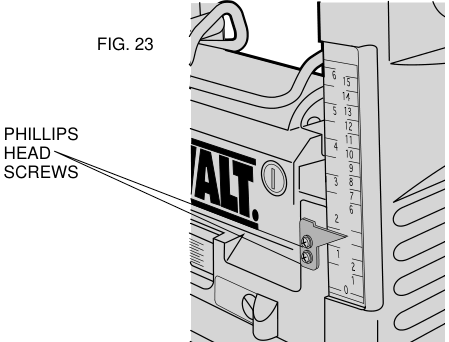

Installing a New Belt

- Turn off and unplug the planer.

- Remove the two Phillips head screws from the front and back of the right side cover.

- Lift the entire cover straight up and pull the bottom out of the slot.

- Notice the grooves inside the belt. (Figure 27). Start the belt on the top pulley (A) as shown in (Figure 28). Guide the belt between the lower pulley and the height adjustment screw (Figure 29). Rotate the belt to keep it engaged on the small pulley.

- Reinstall the side cover and the screws.

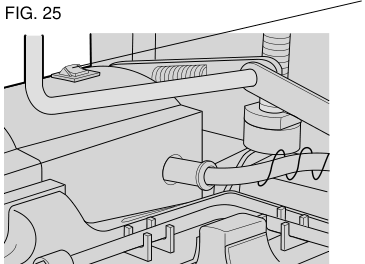

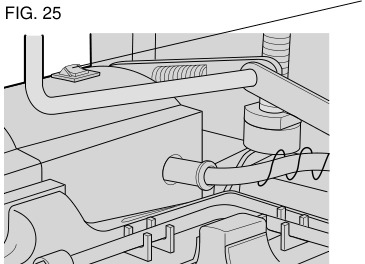

Reset Button

Your planer is equipped with an at18 amp circuit breaker. If your planer becomes overloaded and stops operating, turn off the planer and press in the reset button (Figure 25).

Maintenance

Brushes

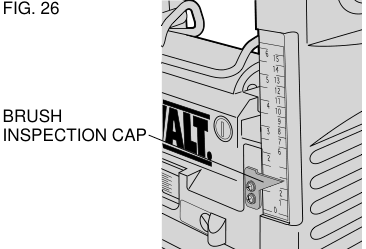

Inspect carbon brushes regularly by unplugging tool, removing the brush inspection cap (Figure 26) and withdrawing the brush assembly.

Keep brushes clean and sliding freely in their guides. Always replace a used brush in the same orientation in the holder as it was prior to its removal. Carbon brushes have varying symbols stamped into their sides, and if the brush is worn down to the line closest to the spring, they must be replaced. Use only identical DEWALT brushes.

New brush assemblies are available at DeWALT service centers. Run the tool unloaded for 10 minutes before using new brushes.

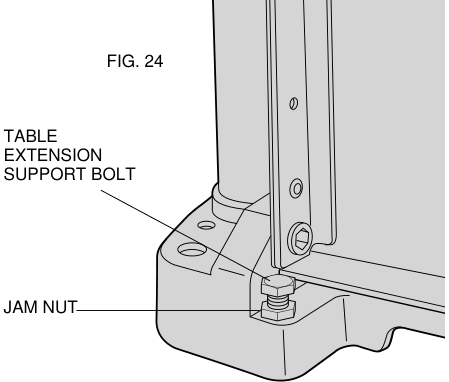

Levelling the Table Extensions

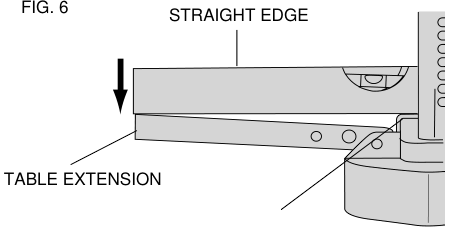

After extended use, the table extensions might become slightly out of level. To ensure that the tables are level, place a straight edge on the table extension and the main table (Figure 6).

Calibrating the Depth Adjustment Scale

The depth adjustment scale on your planer is set at the factory. However, with extended use, the depth adjustment scale could show an incorrect measurement.

To check the depth adjustment scale, plane a piece of wood, noting the measurement. Your finished thickness matches the workpiece. Adjust the pointer up or down until its reading matches the finished thickness of the workpiece.

Important

To assure proper SAFETY and RELIABILITY, repairs, maintenance and adjustment (including brush inspection and replacement) should be performed by authorized service centers or other qualified service organizations, always using identical replacement parts.

Full Warranty

DeWALT heavy duty industrial tools are warranted for one year from date of purchase. We will repair, without charge, any defects due to faulty materials or workmanship. For warranty repair information, call 1-800-4-DeWALT. This warranty does not apply to accessories or damage caused where repairs have been made or attempted by others. This warranty gives you specific legal rights and you may have other rights which vary in certain states or provinces.

In addition to the warranty, DeWALT tools are covered by our:

30 Day No Risk Satisfaction Guarantee

If you are not completely satisfied with the performance of your DeWALT heavy duty industrial tool, simply return it to the participating seller within 30 days for a full refund. Please return the complete unit, transportation prepaid. Proof of purchase may be required.