The DeWALT DCD771 Manual is an indispensable guide for users of the 20V MAX lithium-ion compact drill/driver. This manual offers comprehensive instructions on assembly, operation, and maintenance, ensuring you can effectively utilize the high-performance motor and ergonomic design of this powerful tool. Whether for professional use or DIY projects, the DeWALT DCD771 Manual provides detailed instructions, safety guidelines, and troubleshooting tips to ensure optimum performance and longevity of your drill/driver.

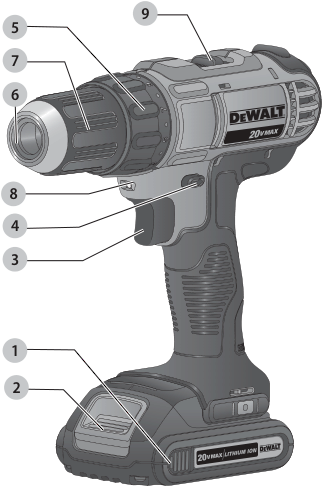

DeWALT DCD771 Components

- Battery pack

- Battery release button

- Variable speed switch

- Forward/reverse lock-off button

- Mode selection collar

- Keyless chuck

- Chuck sleeve

- Worklight

- Speed selector

Maximum Recommended Capacities

- Wood: 1" (25 mm)

- Metal: 1/2" (13 mm)

Intended Use

These drills/drivers are designed for professional drilling and screwdriving applications.

- DO NOT use under wet conditions or in the presence of flammable liquids or gases.

- DO NOT let children come into contact with the tool. Supervision is required when inexperienced operators use this tool.

Definitions: Safety Alert Symbols and Words

- DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

- WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

- CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

- NOTICE: Indicates a practice not related to personal injury which, if not avoided, may result in property damage.

General Power Tool Safety Warnings

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE.

Work Area Safety

- Keep work area clean and well lit. Cluttered or dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust.

- Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical Safety

- Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools.

- Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators.

- Do not expose power tools to rain or wet conditions.

- Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

- When operating a power tool outdoors, use an extension cord suitable for outdoor use.

- If operating a power tool in a damp location is unavoidable, use a ground fault circuit interrupter (GFCI) protected supply.

Personal Safety

- Stay alert, watch what you are doing and use common sense when operating a power tool.

- Use personal protective equipment. Always wear eye protection.

- Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the tool.

- Remove any adjusting key or wrench before turning the power tool on.

- Do not overreach. Keep proper footing and balance at all times.

- Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts.

- If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used.

Power Tool Use and Care

a) Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or remove the battery pack, if detachable, from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

e) Maintain power tools and accessories. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool's operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these instructions , taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

h) Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

Battery Tool Use and Care

a) Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

b) Use power tools only with specifically designated battery packs. Use of any other battery packs may create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails, screws or other small metal objects, that can make a connection from one terminal to another. Shorting the battery terminals together may cause burns or a fire.

d) Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

e) Do not use a battery pack or tool that is damaged or modified. Damaged or modified batteries may exhibit unpredictable behavior resulting in fire, explosion or risk of injury.

f) Do not expose a battery pack or tool to fire or excessive temperature. Exposure to fire or temperature above 265°F (130°C) may cause explosion.

g) Follow all charging instructions and do not charge the battery pack or tool outside the temperature range specified in the instructions. Charging improperly or at temperatures outside the specified range may damage the battery and increase the risk of fire.

Service

a) Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

b) Never service damaged battery packs. Service of battery packs should only be performed by the manufacturer or authorized service providers.

Drill / Driver Safety Warnings

Safety Instructions for All Operations

a) Wear ear protectors when impact drilling. Exposure to noise can cause hearing loss.

b) Brace the tool properly before use. This tool produces a high output torque and without proper bracing the tool during operation, loss of control may occur resulting in personal injury.

c) Hold power tool by insulated gripping surfaces when performing an operation where the cutting accessory or fasteners may contact hidden wiring. Cutting accessory contacting a "live" wire may make exposed metal parts of the power tool "live" and could give the operator an electric shock.

Safety Instructions when Using Long Drill Bits

a) Never operate at higher speed than the maximum speed rating of the drill bit. At higher speeds, the bit is likely to bend if allowed to rotate freely without contacting the workpiece, resulting in personal injury.

b) Always start drilling at low speed and with the bit tip in contact with the workpiece. At higher speeds, the bit is likely to bend if allowed to rotate freely without contacting the workpiece, resulting in personal injury.

c) Apply pressure only in direct line with the bit and do not apply excessive pressure. Bits can bend causing breakage or loss of control, resulting in personal injury.

Additional Safety Warnings for Drills

- Do not operate this tool for long periods of time. Vibration caused by the operating action of this tool may cause permanent injury to fingers, hands, and arms. Use gloves to provide extra cushion, take frequent rest periods, and limit daily time of use.

- Hammer bits and tools get hot during operation. Wear gloves when touching them.

Additional Safety Information

- ANSI Z87.1 eye protection (CAN/CSA Z94.3),

- ANSI S12.6 (S3.19) hearing protection,

- NIOSH/OSHA/MSHA respiratory protection.

- lead from lead-based paints,

- crystalline silica from bricks and cement and other masonry products, and

- arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well-ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

- Wear protective clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote absorption of harmful chemicals. Direct particles away from face and body.

- Use the appropriate dust extractor vacuum to remove the vast majority of static and airborne dust. Failure to remove static and airborne dust could contaminate the working environment or pose an increased health risk to the operator and those in close proximity.

- Use clamps or other practical ways to secure and support the workpiece to a stable platform. Holding the work by hand or against your body is unstable and may lead to loss of control and injury.

- Air vents often cover moving parts and should be avoided. Loose clothes, jewelry or long hair can be caught in moving parts.

Batteries and Chargers

Important Safety Instructions for All Battery Packs

- Do not charge or use the battery pack in explosive atmospheres , such as in the presence of flammable liquids, gases or dust. Inserting or removing the battery pack from the charger may ignite the dust or fumes.

- NEVER force the battery pack into the charger. DO NOT modify the battery pack in any way to fit into a non-compatible charger as battery pack may rupture causing serious personal injury. Consult the chart at the end of this manual for compatibility of batteries and chargers.

- Charge the battery packs only in DeWALT chargers.

- DO NOT splash or immerse in water or other liquids.

- DO NOT allow water or any liquid to enter battery pack.

- Do not store or use the tool and battery pack in locations where the temperature may reach or exceed 104°F (40°C) (such as outside sheds or metal buildings in summer). For best life store battery packs in a cool, dry location.

- Do not incinerate the battery pack even if it is severely damaged or is completely worn out. The battery pack can explode in a fire. Toxic fumes and materials are created when lithium-ion battery packs are burned.

- If battery contents come into contact with the skin, immediately wash area with mild soap and water. If battery liquid gets into the eye, rinse water over the open eye for 15 minutes or until irritation ceases. If medical attention is needed, the battery electrolyte is composed of a mixture of liquid organic carbonates and lithium salts.

- Contents of opened battery cells may cause respiratory irritation. Provide fresh air. If symptoms persist, seek medical attention.

- Battery liquid may be flammable if exposed to spark or flame.

- Never attempt to open the battery pack for any reason. If the battery pack case is cracked or damaged, do not insert into the charger. Do not crush, drop or damage the battery pack. Do not use a battery pack or charger that has received a sharp blow, been dropped, run over or damaged in any way (e.g., pierced with nails, hit with a hammer, stepped on). Damaged battery packs should be returned to the service center for recycling.

Storage Recommendations

Battery Pack Cleaning Instructions

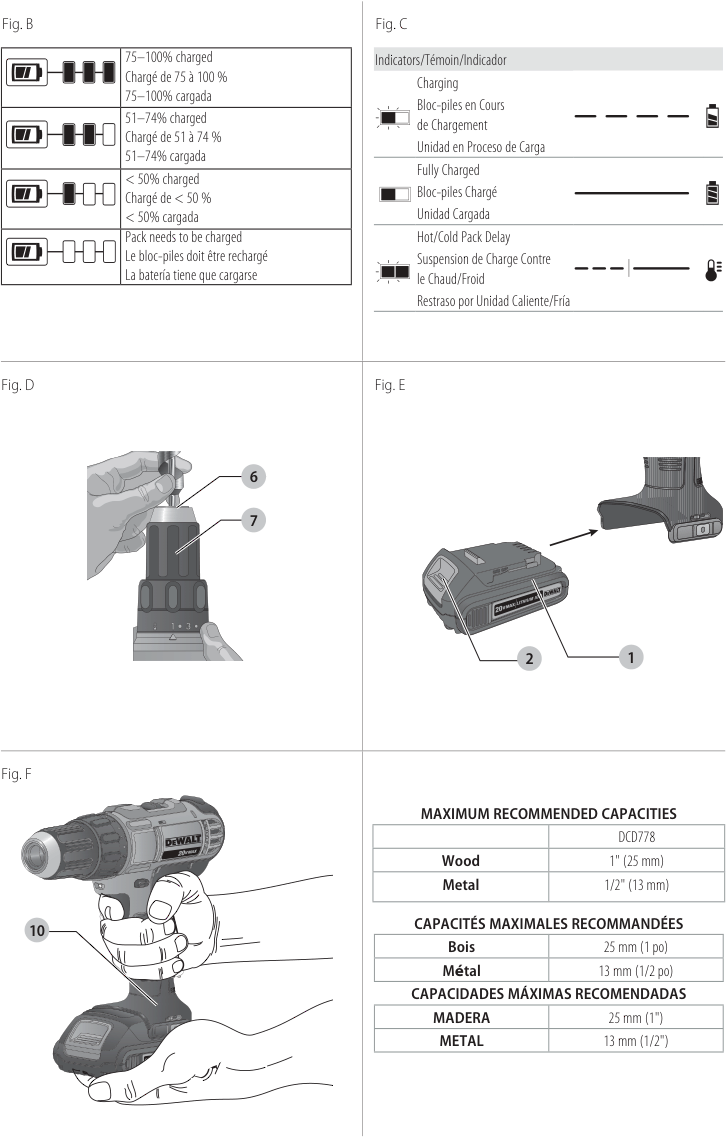

Fuel Gauge Battery Packs (Fig. B)

Some battery packs include a fuel gauge. When the fuel gauge button is pressed and held, the LED lights will indicate the approximate level of charge remaining. This does not indicate tool functionality and is subject to variation based on product components, temperature, and end-user application.

Transportation

⚠️ WARNING: **Fire hazard.** Do not store, carry, or transport the battery pack so that metal objects can contact exposed battery terminals. For example, do not place the battery pack in aprons, pockets, toolboxes, product kit boxes, drawers, etc., with loose nails, screws, keys, coins, hand tools, etc. When transporting individual battery packs, make sure that the battery terminals are protected and well insulated from materials that could contact them and cause a short circuit.

Shipping the DeWALT FLEXVOLT™ Battery Pack

The DeWALT FLEXVOLT™ battery pack has a battery cap that should be used when shipping the battery pack.

In this example, the battery pack is three batteries with 40 Watt hours each when using the cap. Otherwise, the battery pack is one battery with 120 Watt hours.

The RBRC® Seal

Important Safety Instructions for All Battery Chargers

- DO NOT attempt to charge the battery pack with any chargers other than a DeWALT charger. DeWALT chargers and battery packs are specifically designed to work together.

- These chargers are not intended for any uses other than charging DeWALT rechargeable battery packs. Charging other types of battery packs may cause them to overheat and burst, resulting in personal injury, property damage, fire, electric shock or electrocution.

- Do not expose the charger to rain or snow.

- Do not allow water or any liquid to enter charger.

- Pull by the plug rather than the cord when disconnecting the charger. This will reduce the risk of damage to the electric plug and cord.

- Make sure that the cord is located so that it will not be stepped on, tripped over or otherwise subjected to damage or stress.

- Do not use an extension cord unless it is absolutely necessary. Use of improper extension cord could result in risk of fire, electric shock or electrocution.

- When operating a charger outdoors, always provide a dry location and use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

- An extension cord must have adequate wire size (AWG or American Wire Gauge) for safety. The smaller the gauge number of the wire, the heavier the cord and thus the greater its capacity. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The following table shows the correct size to use depending on the total length of all extension cords plugged together, and the nameplate ampere rating. If in doubt, use the next heavier gauge.

| Ampere Rating | 25 ft (7.6 m) | 50 ft (15.2 m) | 100 ft (30.5 m) | 150 ft (45.7 m) |

|---|---|---|---|---|

| 0 - 6 | 18 AWG | 16 AWG | 16 AWG | 14 AWG |

| 6 - 10 | 18 AWG | 16 AWG | 14 AWG | 12 AWG |

| 10 - 12 | 16 AWG | 16 AWG | 14 AWG | 12 AWG |

| 12 - 16 | 14 AWG | 12 AWG | Not Recommended | Not Recommended |

- Do not place any object on top of the charger or place the charger on a soft surface that might block the ventilation slots and result in excessive internal heat. Place the charger in a position away from any heat source. The charger is ventilated through slots in the top and the bottom of the housing.

- Do not operate the charger with a damaged cord or plug. Have them replaced immediately.

- Do not operate the charger if it has received a sharp blow, been dropped or otherwise damaged in any way. Take it to an authorized service center.

- Do not disassemble the charger; take it to an authorized service center when service or repair is required. Incorrect reassembly may result in a risk of electric shock, electrocution or fire.

- The charger is designed to operate on standard 120V household electrical power. Do not attempt to use it on any other voltage.

- Foreign materials of a conductive nature, such as, but not limited to, grinding dust, metal chips, steel wool, aluminum foil or any buildup of metallic particles should be kept away from the charger cavities and ventilation slots.

- Always unplug the charger from the power supply when there is no battery pack in the cavity.

Charging a Battery (Fig. C)

To charge the battery:

- Plug the charger into an appropriate outlet.

- Insert and fully seat battery pack. Red charging light will continuously blink while charging.

- Charging is complete when the red charging light remains continuously ON. Battery pack can be left in charger or removed. Some chargers require the battery pack release button to be pressed for removal.

- Charger will not charge a faulty battery pack, which may be indicated by the light staying OFF. Take charger and battery pack to an authorized service center if light stays OFF.

Hot/Cold Pack Delay

When the charger detects a battery pack that is too hot or too cold, it automatically starts a Hot/Cold Pack Delay, suspending charging until the battery pack has reached an appropriate temperature. The charger then automatically switches to the pack charging mode. This feature ensures maximum battery pack life.

A cold battery pack may charge at a slower rate than a warm battery pack.

The hot/cold pack delay will be indicated by the red light continuing to blink but with the yellow light continuously ON. Once the battery pack has reached an appropriate temperature, the yellow light will turn OFF and the charger will resume the charging procedure.

The DCB118 and DCB1112 chargers are equipped with an internal fan designed to cool the battery pack. The fan will turn on automatically when the battery pack needs to be cooled.

Electronic Protection System

Li-Ion tools are designed with an Electronic Protection System that will protect the battery pack against overloading, overheating or deep discharge. The tool will automatically turn off and the battery pack will need to be recharged.

Important Charging Notes

- The charger and battery pack may become warm to the touch while charging. This is a normal condition, and does not indicate a problem. To facilitate the cooling of the battery pack after use, avoid placing the charger or battery pack in a warm environment such as in a metal shed or an uninsulated trailer.

- If the battery pack does not charge properly: a. Check operation of receptacle by plugging in a lamp or other appliance; b. Check to see if receptacle is connected to a light switch which turns power off when you turn out the lights; c. If charging problems persist, take the tool, battery pack and charger to your local service center.

- You may charge a partially used pack whenever you desire with no adverse effect on the battery pack.

Charger Cleaning Instructions

⚠️ WARNING: **Shock hazard.** Disconnect the charger from the AC outlet before cleaning. Dirt and grease may be removed Proper hand position requires one hand on the main handle and the other hand holding the battery pack.

Variable Speed Trigger and Forward/Reverse Control Button (Fig. A)

The tool is turned on and off by pulling and releasing the variable speed trigger. The farther the trigger is depressed, the higher the speed of the tool. Your tool is equipped with a brake. The chuck will stop as soon as the trigger switch is fully released.

A forward/reverse control button determines the rotational direction of the tool and also serves as a lock-off button.

- To select forward rotation (clockwise), release the trigger and depress the forward/reverse control button on the right side of the tool.

- To select reverse (counterclockwise), depress the forward/reverse control button on the left side of the tool.

NOTE: The center position of the control button locks the tool in the off position. When changing the position of the control button, be sure the trigger is released.

NOTE: Continuous use in variable speed range is not recommended. It may damage the switch and should be avoided.

NOTE: The first time the tool is run after changing the direction of rotation, you may hear a click on start up. This is normal and does not indicate a problem.

Worklight (Fig. A)

The worklight is activated when the trigger switch is depressed, and will automatically turn off 20 seconds after the trigger switch is released. If the trigger switch remains depressed, the worklight will remain on.

NOTE: The worklight is for lighting the immediate work surface and is not intended to be used as a flashlight.

Performing an Application (Fig. A)

WARNING: To reduce the risk of personal injury, ALWAYS ensure workpiece is anchored or clamped firmly.

WARNING: Always wait until the motor has come to a complete standstill before changing the direction of rotation.

Prior to Performing Work

- Set the speed selector. Refer to Speed Selection.

- Install the appropriate bit or accessory into the chuck. Refer to Installing a Bit or Accessory into a Keyless Chuck.

WARNING:

- Do not use this tool to mix or pump easily combustible or explosive fluids (benzine, alcohol, etc.).

- Do not mix or stir flammable liquids labeled accordingly.

Screwdriving

Your tool has a clutch with adjustable torque for driving and removing a wide array of fastener shapes and sizes. The numbers 1–15 on the mode selection collar are used to set a torque range for screwdriving. The higher the number on the collar, the higher the torque and the larger the fastener which can be driven.

- Turn the mode selection collar to the desired position. Refer to Mode Selection.

- Pull the trigger switch applying pressure in a straight line with the bit until the fastener is seated at the desired depth in the workpiece.

Recommendations for Screwdriving

- Start with lower torque settings, then advance to higher torque settings to avoid damage to the workpiece or fastener.

- Make some practice runs in scrap or on unseen areas of the workpiece to determine the proper position of the mode selection collar.

Drilling

- Turn the mode selection collar to the drill symbol. Refer to Mode Selection.

- Place drill bit in contact with the workpiece. NOTE: Use sharp drill bit only.

- Pull the trigger switch applying pressure in a straight line with the bit until it reaches the desired depth. WARNING: Drill may stall if overloaded causing a sudden twist. Always expect the stall. Grip the drill firmly to control the twisting action and avoid injury.

- Keep the motor running when pulling the bit back out of a drilled hole to prevent jamming.

Recommendations for Drilling

- When drilling, always apply pressure in a straight line with the bit, but do not push hard enough to stall the motor or deflect the bit.

- IF THE DRILL STALLS:

- RELEASE TRIGGER SWITCH IMMEDIATELY, remove drill bit from work, and determine cause of stalling.

- DO NOT DEPRESS TRIGGER SWITCH ON AND OFF IN AN ATTEMPT TO START A STALLED DRILL—THIS CAN DAMAGE THE DRILL.

- To minimize stalling or breaking through the material, reduce pressure on drill and ease the bit through the last fractional part of the hole.

- Large holes (5/16” to 1/2” 7.9 mm to 12.7 mm ) in steel can be made easier if a pilot hole (5/32” to 3/16” 4 mm to 4.8 mm ) is drilled first.

- If drilling thin material or material that is prone to splinter, use a wood “back-up” block to prevent damage to the workpiece.

Maintenance

Cleaning

Accessories

Recommended accessories for use with your tool are available at extra cost from your local dealer or authorized service center. If you need assistance in locating any accessory, please contact DEWALT call 1-800-4-DEWALT (1-800-433-9258) or visit our website: www.dewalt.com.

Repairs

The charger and battery pack are not serviceable. There are no serviceable parts inside the charger or battery pack.

Register Online

Thank you for your purchase. Register your product now for:

- WARRANTY SERVICE: Registering your product will help you obtain more efficient warranty service in case there is a problem with your product.

- CONFIRMATION OF OWNERSHIP: In case of an insurance loss, such as fire, flood or theft, your registration of ownership will serve as your proof of purchase.

- FOR YOUR SAFETY: Registering your product will allow us to contact you in the unlikely event a safety notification is required under the Federal Consumer Safety Act.

- Register online at www.dewalt.com

Three Year Limited Warranty

For warranty terms, go to . To request a written copy of the warranty terms, contact: Customer Service at DEWALT Industrial Tool Co., 701 East Joppa Road, Towson, MD 21286 or call 1-800-4-DEWALT (1-800-433-9258).