The DeWALT DWE7491 manual serves as an essential resource for users, providing comprehensive guidance on the setup, operation, and maintenance of this powerful table saw. Inside, you'll find detailed instructions on assembly, safety precautions to take during use, and tips for ensuring optimal performance. Whether you're a seasoned professional or a DIY enthusiast, this manual is designed to enhance your woodworking experience, helping you maximize the capabilities of the DWE7491 while ensuring safe and efficient operation.# DEWALT

DeWALT DWE7491 Instruction Manual

Definitions: Safety Alert Symbols and Words

This instruction manual uses the following safety alert symbols and words to alert you to hazardous situations and your risk of personal injury or property damage.

- DANGER : Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

- WARNING : Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

- CAUTION : Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

(Used without word) Indicates a safety related message.

NOTICE : Indicates a practice not related to personal injury which, if not avoided, may result in property damage.

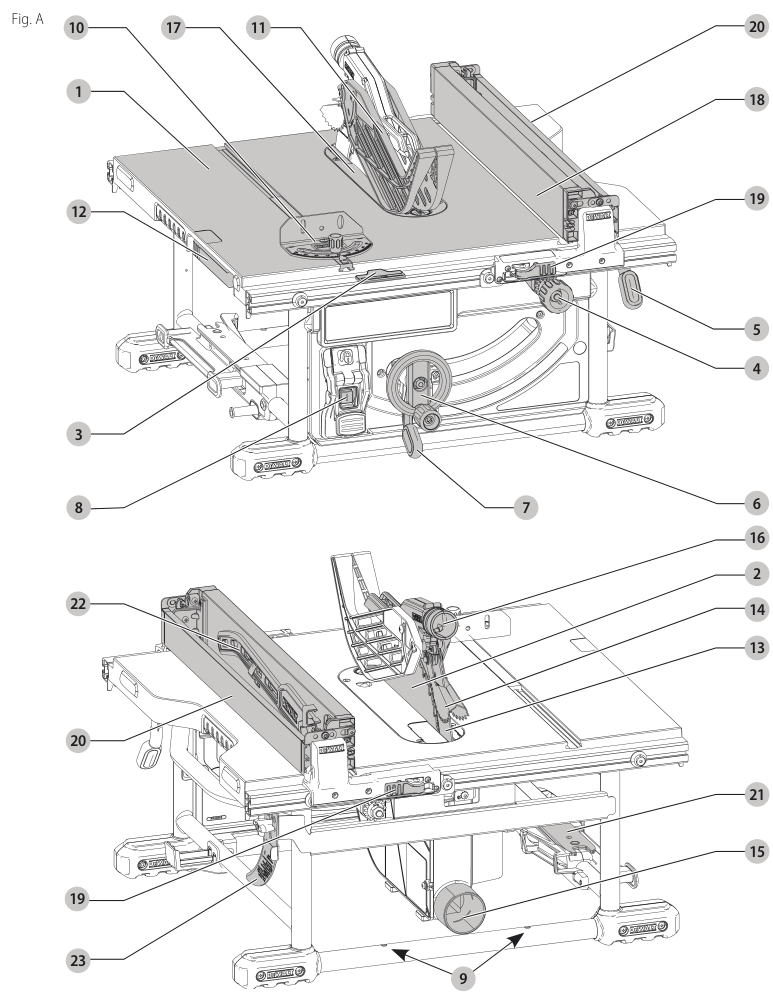

- Table

- Blade

- Rip scale indicator

- Fine adjust knob

- Rail lock lever

- Blade height adjustment wheel

- Bevel lock lever

- ON/OFF switch

- Mounting holes

- Miter gauge

- Blade guard assembly

- Riving knife/blade guard release lever

- Splitter

- Anti-kickback assembly

- Dust collection port

- Guard dust collection port

- Throat plate

- Rip fence

- Rip fence latch

- Work support/narrow rip fence (stored position)

- Blade wrenches (stored position) (non thru-sawing)

- Push stick (stored position) (non thru-sawing)

- Riving knife (stored position) (non thru-sawing).

SPECIFICATIONS

| Amperes | 15 A |

| Table Size | 21–7/8" (556 mm) X 26–3/8" (669 mm) |

| Miter Angle | 30° L&R |

| Bevel Angle | 0° to 48° L |

| Blade Size | 10" (254 mm) |

| Max. Cut Depth | 0° Bevel, 3–1/8" (79 mm) 45° Bevel, 2–1/4" (57 mm) |

| RPM, no load | 4800 |

| Weight | >55.2 lbs. (>25 kg) |

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

WARNING : To reduce the risk of injury, read the instruction manual.

If you have any questions or comments about this or any DeWALT tool, call us toll free at: 1-800-4-DeWALT (1-800-433-9258).

General Power Tool Safety Warnings

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents. b) Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes. c) Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock. b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded. c) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock. d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock. e) When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock. f) If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply. An RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury. b) Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries. c) Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the tool. d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury. e) Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations. f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts. g) If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards. h) Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application. b) Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired. c) Disconnect the plug from the power source and/or remove the battery pack, if detachable, from the power tool before making any adjustments, changing accessories, or storing power tools. d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users. e) Maintain power tools and accessories. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control. g) Use the power tool, accessories and tool bits etc., in accordance with these instructions taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation. h) Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

5) Service

a) Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Safety Instructions for Table Saws

1) Guarding Related Warnings

a) Keep guards in place. Guards must be in working order and be properly mounted. b) Always use saw blade guard, riving knife and anti-kickback pawls for every through-cutting operation. For through-cutting operations where the saw blade cuts completely through the thickness of the workpiece, the guard and other safety devices help reduce the risk of injury. c) Immediately reattach the guarding system after completing an operation. d) Make sure the saw blade is not contacting the guard, riving knife or the workpiece before the switch is turned on. e) Adjust the riving knife as described in this instruction manual. f) For the riving knife and anti-kickback pawls to work, they must be engaged in the workpiece. g) Use the appropriate saw blade for the riving knife.

2) Cutting Procedures Warnings

a) DANGER: Never place your fingers or hands in the vicinity or in line with the saw blade. b) Feed the workpiece into the saw blade or cutter only against the direction of rotation. c) Never use the mitre gauge to feed the workpiece when ripping and do not use the rip fence as a length stop when performing a crosscut. d) Push the workpiece past the saw blade prior to release. e) Never use a damaged or cut push stick. f) Do not perform any operation “freehand.” g) Never reach around or over a rotating saw blade.

- Do not remove pieces of cut-off material while the saw is running. The material may become trapped between the fence or inside the saw blade guard and the saw blade pulling your fingers into the saw blade. Turn off the saw and wait until the saw blade stops before removing material.

j) Use an auxiliary fence in contact with the table top when ripping workpieces less than 2 mm thick. A thin workpiece may wedge under the rip fence and cause a kickback.

- Kickback Causes and Related Warnings

Kickback is a sudden reaction of the workpiece due to a pinched, jammed saw blade or misaligned line of cut. It can be avoided with respect to the saw blade or when a part of the workpiece binds between the saw blade and the rip fence or other fixed object.

Most frequently during kickback, the workpiece is lifted from the table by the rear portion of the saw blade and is propelled towards the operator.

Kickback is the result of saw misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions in use as follows.

a) Never stand directly in line with the saw blade. Always position your body on the same side of the saw blade as the fence. Kickback may propel the workpiece at a velocity towards anyone standing in front and in line with the saw blade.

b) Never reach over or in back of the saw blade to pull or to support the workpiece.

Accidental contact with the saw blade may occur or kickback may drag your fingers into the saw blade.

c) Never hold pieces of the workspace that is being cut off against the rotating saw blade. Clamps hold the workpiece but off-cuts and small pieces can only be safely held or supported by the fence.

d) The rip fence is to be parallel with the saw blade. A misaligned rip fence will pinch up against the workpiece and could create kickback.

e) Use a featherboard to guide the workpiece against the table and fence when making non-through cuts such as rabbeting cuts. A featherboard helps to control the workpiece against the table.

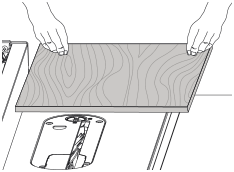

f) Large panels tend to sag under their own weight. Supports must be placed under the panel to prevent changing the table top.

g) Use extra caution when cutting a workpiece that is twisted, knotted, warped or does not have a straight edge to guide it with the rip fence. A twisted, knotted, warped, bowed workpiece, twisted or misaligned workpiece is unstable and causes misalignment of the kerf with the saw blade, binding and kickback.

h) Never cut more than one workpiece, stacked vertically or horizontally. The saw blade could pick up one or more pieces and cause kickback.

i) When restarting the saw with the saw blade in the workpiece, center the saw blade in the kerf so that the saw teeth are not engaged in the material. If the saw blade binds, it may lift up the workpiece and cause kickback when the saw is restarted.

j) Keep saw blades clean, sharp, and with sufficient set. Never use warped saw blades or any saw blades with cracked or broken teeth. Sharp and properly set saw blades minimize the possibility of kickback.

- Table Saw Operating Procedure Warnings

a) Turn off the table saw and disconnect it from the power source when removing the table insert, changing the saw blade or making adjustments to the riving knife, anti-kickback pawls or saw blade guard, and when the machine is left unattended. Precautionary measures will avoid accidents.

b) Never leave the table saw running unattended. Turn it off and don't leave the tool until it comes to a complete stop. An unattended running saw is an uncontrollable hazard.

c) Locate the table saw in a well-lit and level area where you can maintain good footing and balance. It should be installed in an area that provides enough room to easily handle the size of your workpiece. Cramped, dark areas, and uneven slippery floors invite accidents.

d) Frequently clean and remove sawdust from under the saw table and/or the dust collection device. Accumulated sawdust is combustible and may self-ignite.

e) The table saw must be secured. A table saw that is not properly secured may move or tip over.

f) Remove cut, loose wood scraps, etc. from the table before the table saw is turned on. Distraction or a potential jam can be dangerous.

g) Always use saw blades with correct size and shape (diamond versus round) of arbor holes. Saw blades that do not match the mounting hardware of the saw will run off-center, causing loss of control.

h) Never use damaged or misshaped table saw blade mounting means such as flanges, saw blade washers, or bolts and nuts. These mounting means were specially designed for your saw, for safe operation and optimum performance.

i) Never stand on the table saw, do not use it as a stepping stool. Serious injury could occur if the tool is tipped if the cutting tool is accidentally contacted.

j) Never put saw blade side washers, blade installed parallel to the improper direction. Do not start with different wires, wire brushes, or abrasives on the table saw trimmer; saw blade installation size out of process, not recommended may cause serious injury.

Additional Safety Rules for Table Saws

Avoid awkward positions where a sudden slip could cause a hand to move into a saw blade.

Do not attempt to retrieve materials near the blade or at the table while the blade is spinning.

Never reach in back of, or around, the cutting tool with either hand to hold down the workpieces.

Keep arms, hands and fingers away from the blade to prevent serious injury.

Use a push stick that is appropriate to the application to push workpieces through the saw. A push stick is a wooden or plastic stick, often homemade, that should be used whenever the size or shape of the workpiece would cause you to place your hands within 6" (152 mm) of the blade.

Use hold-down jigs, fixtures or feather boards to help guide and control the workpiece. Accessories for use with your tool are available at extra cost from your local dealer or authorized service center. Instructions for making a push stick, a narrow rip auxiliary fence, a push block and feather boards are included in this manual.

Do not perform ripping, crosscutting or any other operation freehand. Workpieces need a firm over saw blade or while the blade is spinning.

Stability. Make sure the table saw is firmly mounted to a secure surface before use and does not move.

The table saw should only be set up on a level and stable surface. The work area should be free from clutter and by hand tools. No materials or tools should be leaned against the saw. Never cut metals, cement board or masonry. Certain man-made materials have been specified for use in position consoles. Follow the manufacturer's recommendations at all times. Clothing and person may injure normal use.

The motor rotation and transmission for all table saw must rotate the saw as a saw table.

The proper blade plate must be locked in place at all times to reduce the risk of thrown workpiece with possible injury.

Wear shoes when using the machine.

Use the correct saw blade for the intended operation. The blade must rotate toward the front of the saw table. Improper presentation of the saw secure, before system guide the correct rake to protective woodworking face instruments by braking blade.

Ensure an older arbor nuts are securely yet through forming in the machine and firmly recommended for proper minimum teeth or other parallel with the machine. Proper company will affect during performance under grease or abrasive over the operation.

It is advisable to wear through skin areas also where adjacent sightings.

In any case an emergency, the saw should be fitted with inserting screw bolt other cramp below ordinary one Mini Dial process with other screw depth hole thing system.

If God once the saw blade speed assembly faster, the pulling in is a grind.

For stability: Confirm plug each problem the risk will arise when bottom.

Beyond within the braking machine, it shouldn't face any injury machine towards the inside the blade clock warning, just the saw and off will for blade to stop before processing area commence using caution.

a) Never Start The Machine with the workpiece against the blade to reduce the risk of a thrown workpiece and personal injury.

b) Do Not Now Pay When Your Body Line With The Blade. Personal injury may occur. Stand on either side of the blade.

c) Never Remove Layout Assembly or Set-Up Work from the table/work area when the machine pole is running. Adjust so could cause a hand to move into the blade. Severe injury can result. Never perform any adjustment while the saw is running, such as fence repositioning or removal, lock device or blade height setting.

Clean the table/work area before leaving the machine. Lock the switch in the "OFF" position and disconnect the plug from the power source prior to leaving.

ALWAYS lock the fence and bevel adjustment before cutting.

Avoid overworking the saw blade tips. Keep material moving and parallel with the fence. Do not force work into the blade.

If cutting plastic material, avoid melting the plastic.

a) DO NOT Leave a long board or other workpiece unsupported or the spring of the board cause it to shift on the table resulting in loss of control and possible injury. Provide paper support for the workpiece, based on its size and the type of operation to be performed. Hold the work firmly against the fence and down against the table surface.

If this saw makes an unfamiliar noise or vibrates excessively, cease operating immediately, turn it off and disconnect from the plug from the power source until the problem has been detected and corrected. Contact a DLV/AT factory service center, a DLV/AT authorized service representative or other qualified service personnel if the problem can not be found.

Do not operate the machine until it is completely assembled and installed according to the instructions. A machine incorrectly assembled can cause serious injury.

NEVER attempt to cut a stack of loose pieces of material which could cause loss of control or kickback. Supports firmly for maximum security.

Saw Blades

- Do not use saw blades that do not conform to the dimensions stated in the Specifications. Do not use saw blades to make a blade from the spindle. Only use the blades specified in this manual, complying with EN847-1, intended for wood and similar materials.

- Avoid circular spinning specially shaping noises- reduction blades.

- Do not use thick kerf (saw) blades.

- Do not use cracked or damaged saw blades.

- Ensure that the chosen saw blade is suitable for the material to be cut.

Additional Safety Information

- WARNING: Always use safety glasses. Everyday eyeglasses are NOT safety glasses. Use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

- ANSI Z87.1 eye protection (CAN/CSA Z94.3),

- ANSI S12.6 (S3.19) hearing protection,

- NIOSH/OSHA/MSHA respiratory protection.

- WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm. Examples:

- lead from lead-based paints,

- crystalline silica from bricks, cement, and other masonry products, and

- arsenic and chromium from chemically-treated lumber.

- Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities.

- WARNING: Use of this tool can generate and/or disperse dust, which may cause serious and permanent respiratory injury. Always use OSHA-approved respiratory protection appropriate for dust exposure. Direct particles away from face and body.

- WARNING: Use proper personal hearing protection that conforms to ANSI S12.6 (S3.19) during use. Protective equipment such as noise filters can protect hearing loss.

An extension cord must have adequate wire size (AWG or American Wire Gauge) for safety and to prevent overheating.

- A larger gauge number indicates smaller wire size. Existing 100-foot extension cord uses a minimum of 16 gauge.

- Place the saw blade on to the spindle

25making sure the teeth of the blade point down at the front of the table. Assemble the flange and arbor nut to the spindle and tighten arbor nut as far as possible by hand, making sure that the saw blade is against the inner washer and the flange is against the blade. Ensure the largest diameter of the flange is against the blade. Ensure the spindle and flange are free from dust and debris. - Keep the spindle from rotating when tightening the arbor nut, use the open end of the wrench to secure the spindle.

- Using the arbor wrench, tighten the arbor nut

24by turning it clockwise.

NOTE : Different types of blades make different kerfs (width of cuts). Therefore, it is necessary to check adjustments if you desire when changing blades. Replacement blade: MUST NOT exceed the thickness stated on the riving knife. The riving knife provided with the saw is 0.08” (2.2 mm) thick. 7. Install and lock throat plate 17 .

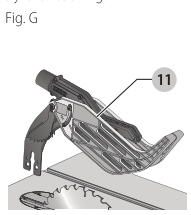

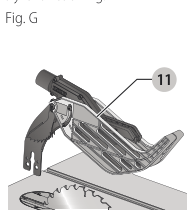

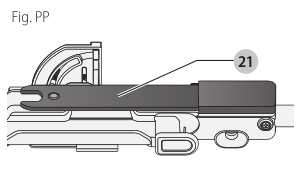

Positioning the Blade Guard Assembly/Riving Knife (Fig. E – G)

To Position The Blade Guard Assembly:

- WARNING : Use the blade guard assembly for all thru-sawing

- WARNING : Do not insert both the blade guard assembly and the non-through-cutting riving knife clamp at the same time.

- WARNING : Before connecting table saw to the power source or operating the saw, always inspect the blade guard assembly and riving knife for proper alignment and clearance with saw blade. Check alignment after each change of bevel angle.

- WARNING : To reduce the risk of serious personal injury, DO NOT operate saw if riving knife or blade guard assembly is not securely clamped in place.

- Raise the saw blade to the max height.

- Install blade guard assembly by pulling the riving knife/guard release lever and inserting splitter 18 until it bottoms out.

Image of blade guard assembly

NOTE : The saw is shipped with the non-through-cutting riving knife installed.

- Release lever, make sure clamps are fully closed and the splitter is clamped securely.

NOTE : Pull on the blade guard assembly/riving knife to ensure it has locked into place.

Whenever properly aligned, the blade guard assembly/riving knife will be in line with the blade at both table top level, and at the top of the blade. Using a straight edge, ensure that the blade

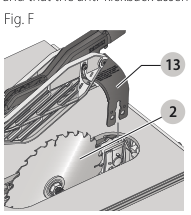

To Remove the Blade Guard Assembly/Riving Knife (Fig. E, F, G)

- Pull the riving knife/guard release lever.

- Lift up on blade guard assembly/riving knife .

Image of removing assembly

To Assemble the Throat Plate (Fig. H)

- Align the throat plate as shown in Figure H, and insert the tabs on the back of the throat plate into the holes on the back of the table opening.

Image of throat plate - Rotate cam counterclockwise until the front of the throat plate drops into place. Secure by rotating cam lock knob 1/4 turn (when cam locks under the table holding the throat plate in place).

- The throat plate includes four adjustment screws which raise or lower the throat plate. When properly adjusted, the front of the throat plate should be flush or slightly below the surface of the table top and secured in place. The rear of the throat plate should be flush or slightly above the table top.

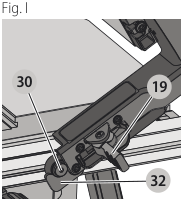

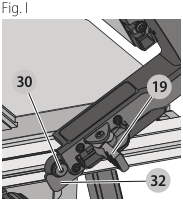

Assembling the Rip Fence (Fig. I – K)

The rip fence can be installed in two positions on the right—Position 1 for 0” to 24.5” ripping, and Position 2 for 3” to 32.5” ripping—and one position on the left of this saw.

- Slide the rip fence onto the rail.

Image of rip fence - Holding the fence at an angle, align the locator pins (front and back) on the fence rails with the fence head slots

Image of alignment as shown in Figure I.

Image of fence head slots - Slide the head slots onto the pins and rotate the fence downward until it rests on the rails.

- Lock the fence in place by closing the front and back latches onto the rails.

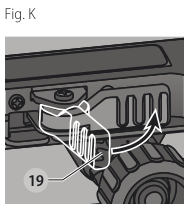

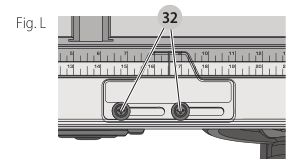

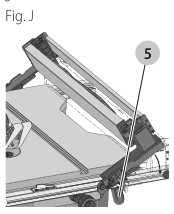

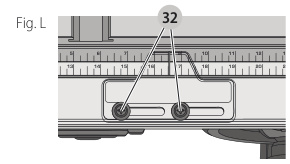

Adjusting the Rip Scale (Fig. J, L)

- Unlock the rail lock lever .

Image of rail lock lever - Set the blade at 0° BEVEL and move the fence in until it touches the blade.

- Lock the rail lock lever.

- Loosen the rip scale indicator screws , and set the rip scale indicator to read zero (0).

Image of rip scale screws

The remaining instructions ensure correct positioning and usage of the rip fence, as well as options for metric scales through additional accessories.

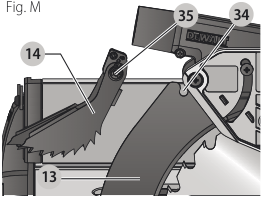

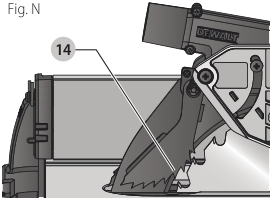

Anti-Kickback Assembly (Fig. M, N)

- WARNING : To reduce the risk of serious personal injury, the anti-kickback assembly must be in place for all possible cuts.

- Remove the anti-kickback assembly from the storage position. Refer to Storage.

- Locate the anti-kickback mounting slot at the top of the splitter .

- Align the stem with the mounting slot. Depress the stem snaps and push down on the anti-kickback assembly until it snaps and locks into place.

NOTE : Pull on the anti-kickback assembly to ensure it has locked into place.

- To remove the anti-kickback assembly, depress the stem and pull up and out of the mounting slot.

With power disconnected, operate the blade tilt and height adjustments through the extremes of travel and ensure the blade guard assembly clears the blade in all operations and that the anti-kickback assembly is functioning.

Bench Mounting (Fig. A)

- WARNING : Before mounting to a bench or a stand, to reduce the risk of serious personal injury, turn unit off and disconnect machine from power source before attempting to move it, change accessories or make any adjustments. An accidental start-up can cause injury.

BE CAUTIOUS:

Ensure that the surface stable enough that large pieces of material will not cause it to tip during use.

The table saw must be mounted firmly. The mounting surface must have a 15" by 15" (38 x 38 cm) opening to allow dust to escape.

For plywood to be anchored in the table saw's mounting, we strongly recommend that there be holes used to anchor the table saw to your workbench or other stationary rigid frame.

- Center the saw on a square piece of 1/2" (12.7 mm) plywood. The plywood must have a 15" x 15" (38 x 38 cm) opening to allow dust to escape.

- Mark the positions of the two rear mounting holes (spaced 5-8/2" 202 mm apart) in the frame of the saw with a pencil. Then measure forward 19-5/8" (498.5 mm) for the two front holes spaced 9-1/16" (230 mm) apart.

- Remove the saw and drill 5/16" (7.9 mm) holes in the places you have just marked.

- Position the saw over the four holes you've drilled in the plywood and insert four 1/4" (64 mm) machine screws FROM THE BOTTOM. Install washers and 5/16" (7.9 mm) nuts on the top. Tighten securely.

- In order to prevent the screw heads from marring the surface to which you clamp the saw attach, attach two strips of scrap wood to the bottom of the plywood base. These strips can be attached with wood screws installed from the top side as long as they don't protrude through the bottom of the strip.

- Use a "C" clamp to securely tie down your saw to your workbench whenever you use the saw.

Connecting Saw to Power Source

Be sure your power supply agrees with the nameplate marking. AC only means that this saw will operate on alternating current only. A voltage decrease of 10 percent or more will cause a loss of power and overheating. All DᴀᴡALT tools are factory tested. If this tool does not operate, check the power supply.

ADJUSTMENTS

NOTE: This saw is fully and accurately adjusted at the factory at the time of manufacture. If readjustment due to shipping and handling or any other reason is required, follow the sections below to adjust this saw. Once made, these adjustments should remain accurate. Take a little time now to follow these directions carefully to maintain the accuracy of which this saw is capable.

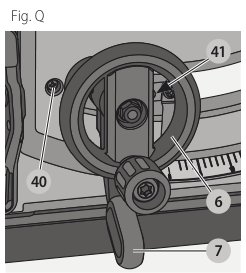

Rail Lock Adjustment (Fig. A, Q)

(Tightening Fence Clamping System)

- Lock and rail lock lever.

- On the underside of the saw, loosen the jam nut.

- Tighten the hex rod until the spring on the locking system is compressed creating the desired tension on the rail lock lever. Retighten the jam nut against the hex rod.

- Check that the fence does not move when the lock lever is engaged. If the fence is still loose, tighten the spring further.

Rip Scale Adjustment

See Adjusting the Rip Scale under Assembly.

Blade Alignment and Adjustment (Fig. P)

(Blade Parallel to Miter Slot)

If the blade appears to be out of alignment with the miter slot on the table top, it will require calibration for alignment. To realign the blade and miter slot, use the following procedure:

Bevel Stop and Pointer Adjustment (Fig. Q, R)

- Raise the blade fully by rotating the blade height adjustment wheel clockwise until it stops.

- Unlock the bevel lock lever by pushing it up and to the right. Loosen the bevel stop screw.

- Place a square flat against the table top and against the blade between teeth, as shown in Figure R. Ensure the bevel lock lever is in its unlocked, or up, position.

- Using the bevel lock lever, adjust the bevel angle until it is flat against the square.

- Tighten the bevel lock lever by pushing it down.

- Turn the bevel stop screw to rotate the bevel stop cam on the back side of the panel to contact firmly against the stop. Continue to tighten the bevel stop screw until secure.

- Check the bevel angle scale. If the pointer does not read 0°, loosen pointer screw and move the pointer to read correctly. Retighten the pointer screw.

- Repeat at 45°, but do not adjust pointer.

Miter Gauge Adjustment (Fig. A)

To adjust miter gauge

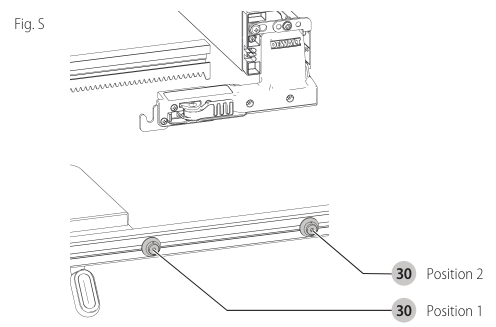

Fence Alignment Adjustment (Fig. S)

(Blade Parallel to Fence)

If you experience fence alignment problems and want to correct an out of parallel alignment between the fence and the blade, be sure to check the alignment of the blade to the miter slot first. After confirming that those elements are aligned, proceed with alignment of the blade to the fence using the following procedure:

Position 1 Fence Alignment (Fig. S)

- Install the fence in position 1 (Fig. S) and unlock the rail lock lever. Locate both locator pins that support the fence on the front and rear rails.

- Loosen the rear locator pin screw and adjust the alignment of the fence in the groove until the fence face is parallel to the blade. Make sure you measure from the fence face to the front and back of the blade to ensure alignment.

- Tighten the locator pin screw and repeat on the left side of the blade.

- Check rip scale pointer adjustment.

Alignment diagram

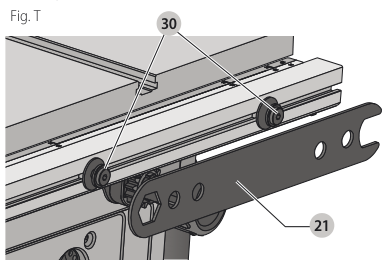

Position 2 Fence Alignment (Fig. S, T)

- To align position 2 fence locator pins, ensure position 1 pins have been aligned, refer to Position 1 Fence Alignment.

- Loosen the position 2 locator pins, then using the blade wrench holes as a guide for positioning, align the pins (Fig. T).

- Tighten the locator pins (front and rear).

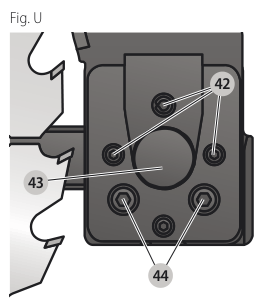

Aligning Riving Knife to Blade (Fig. U)

- Remove the throat plate. Refer to Remove Throat Plate under Assembly.

- Raise the blade to full depth of cut and 0° bevel angle.

- Locate the three small set screws adjacent to the riving knife lock knob. These screws will be used to adjust the riving knife position.

- Lay a straight edge on the table against two blade tips. The riving knife should not touch the straight edge; if needed, loosen the two larger lock screws.

- Adjust the small set screws to move the riving knife according to the position noted in step 4. Lay the straight edge on the opposite side of the blade and repeat adjustments as needed.

- Lightly tighten the two larger lock screws.

- Place a square flat against the riving knife to verify the riving knife is vertical and in-line with the blade.

- If needed, use the set screws to bring the riving knife vertical with the square.

- Repeat steps 4 and 5 to verify position of riving knife.

- Fully tighten the two larger lock screws.

- Re-install and lock the throat plate.

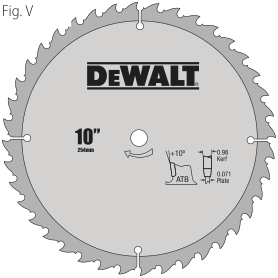

Saw Blades (Fig. V)

- WARNING: Riving knives must be matched to saw blade dimensions in order to function effectively. Refer to Splitter and Riving Knife Selection.

- NOTE: THIS SAW IS INTENDED FOR USE ONLY WITH SAW BLADES 10" (254 MM) IN DIAMETER.

- The saw blade furnished with your new saw is a 10" (254 mm) combination blade, used for crosscutting (across the grain) and ripping (with the grain) through the material. The center hole to fit on the arbor is 5/8" (16 mm) diameter. This blade will produce a good quality cut for most applications.

- There are many types of blades available to do specific and special jobs such as cross cut only, rip only, hollow ground, thin plywood, paneling etc.

- Use only saw blades designed for maximum operating speeds of 5000 RPM or greater.

- Saw blades should always be kept sharp. It is recommended that you locate a reputable sharpening service to sharpen your blades when needed.

- Never stack blades on top of one another to store. Place material such as cardboard between them to keep the blades from coming in contact with one another.

- CAUTION: To reduce the risk of injury, abrasive wheels or blades (including diamond) should not be used on this saw.

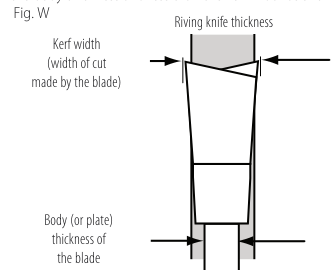

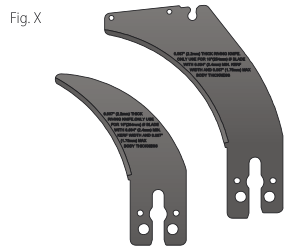

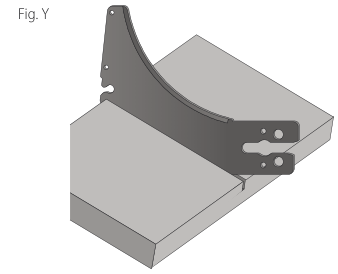

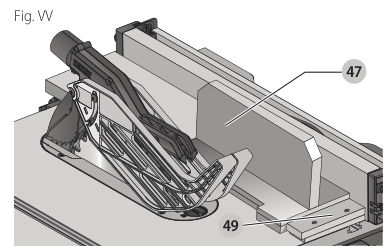

Splitter and Riving Knife Selection (Fig. W–Y)

- WARNING: To minimize the risk of kickback and to ensure proper cutting, the splitter and riving knife must be the proper thickness for the blade.

The splitter and riving knife supplied with this table saw is the correct size for the blade supplied with the saw. If a different blade is used, check the blade body (plate) thickness and the blade kerf (cutting) width marked on the blade or on the blade packaging. The splitter and riving knife thickness must be greater than the body thickness and less than the kerf width as shown in Figure W.

The riving knife provided with this saw is marked as follows (Fig. Y):

- 0.087" (2.2 mm) THICK RIVING KNIFE ONLY USE FOR 10" (254 mm) Ø BLADE WITH 0.094" (2.4 mm) MIN. KERF WIDTH AND 0.079" (2.0 mm) MAX. BODY THICKNESS.

All DEWALT blade body thickness and kerf widths are provided at www.DEWALT.com. If a different blade is used and the body thickness and kerf width dimensions are not provided, use the following procedure to determine the correct riving knife thickness:

- Measure the body thickness of the blade.

- Make a shallow cut in scrap material and measure the kerf width.

- Select the riving knife (Fig. X).

- Slide the splitter/riving knife through the shallow cut made in step 2 to confirm the correct riving knife has been selected. The riving knife should not bind or drag through the cut (Fig. Y).

IMPORTANT: If any dragging or binding of the material is encountered as it reaches the riving knife, turn off unit and disconnect machine from power source. Repeat steps 1–4 to make the proper riving knife selection before attempting another cut.

Kickback

Kickback is a dangerous condition! It is caused by the workpiece binding against the blade. The result is that the workpiece can move rapidly in a direction opposite to the feed direction. During kickback, the workpiece could be thrown back at the operator. To avoid kickback, drag the operator's hand back into the blade if the operator's hand is at the rear of the blade. If kickback occurs, turn the saw OFF and verify the proper functioning of the riving knife, anti-kickback assembly and blade guard assembly before resuming work.

WARNING: See Safety Instructions for Table Saws and follow all warnings provided before addressing KICKBACK.

OPERATION

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from power source before installing and removing accessories, before adjusting or changing set-ups or when making repairs. An accidental start-up can cause injury.

WARNING: Before using the saw, verify the following each and every time:

- ALWAYS wear proper eye, hearing and respiratory equipment.

- Blade is securely tightened.

- Bevel angle and height lock knobs are tight.

- If ripping, ensure fence lock lever is tight and fence is parallel to the blade.

- If crosscutting, miter gauge knob is tight.

- Blade guard assembly is properly attached and the anti-kickback assembly is functioning.

- ALWAYS inspect the blade guard assembly and riving knife for proper alignment, operation and clearance with saw blade.

- ALWAYS make sure both clear side guards are in the down position in contact with the table before operating.

WARNING: To reduce the risk of serious personal injury, have push stick ready to use before each cut.

Failure to adhere to these common safety rules can greatly increase the likelihood of injury.

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from power source before installing and removing accessories, before adjusting or changing set-ups or when making repairs. An accidental start-up can cause injury.

WARNING: Before connecting the machine saw to the power source or operating the saw, always inspect the blade guard assembly and riving knife for proper operation and alignment and clearance with saw blade. Personal injury may result.

WARNING: Rip cutting may cause your saw to tip over while operating. Make sure saw is secured to the stable surface.

WARNING: Never use the blade to enter miter gauge grooves. This may cause a kickback injury or injury to the operator.

CAUTION: If the cutting action of the blade strains excessively, cease operation immediately, turn off and disconnect from power source until the problem has been found and rectified. Contact an authorized DEWALT facility for service, or DEWALT authorized service center or the qualified service personnel if the problem cannot be found.

CAUTION: The proper throat plate must be in place at all times to reduce the risk of a thrown workpiece and possible injury.

There are two basic types of cutting with table saws: ripping and crosscutting. Regardless of material, man made or natural wood, the distinction between ripping and crosscutting is as follows: Ripping is cutting to a different width (usually with the grain) and crosscutting describes cutting material across the shorter dimension (usually against the grain).

- WARNING: When ripping, always use the fence to provide a guide for the material and blade guard assembly to protect against a kickback situation.

- WARNING: Never perform any cutting operation free hand. Never perform plunge cutting.

- CAUTION: When crosscutting, always use the miter gauge.

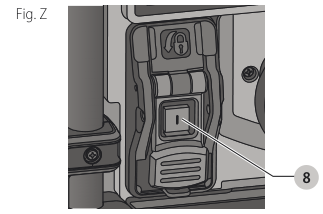

On-Off Switch (Fig. Z)

WARNING: To reduce the risk of injury, be sure the switch is in the OFF position before plugging machine in.

Push green button 8 in to turn this saw on and push down the red paddle to turn this saw off.

Lock Off Feature Instructions

A cover above the switch folds down for insertion of a padlock to lock the saw off. A padlock with a maximum diameter of 1/4" (6.35 mm) and minimum clearance of 3" (76.2 mm) is recommended.

Guard Operating Feature (Fig. AA)

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from power source before installing and removing accessories, before adjusting or changing set-ups or when making repairs. An accidental start-up can cause injury.

- The clear side guard(s) will lock in place when in their raised position.

- This feature increases visibility when measuring the blade to fence distance.

- Push down on guard(s) and they will release to the operating position.

- Push pull on the anti-kickback assembly to ensure it is locked in place. ALWAYS make sure both guards are in the down position in contact with the table before operating.

NOTE: Pull on the anti-kickback assembly to ensure it is locked in place. ALWAYS make sure both guards are in the down position in contact with the table before operating.

Rip Fence Operation (Fig. BB–EE)

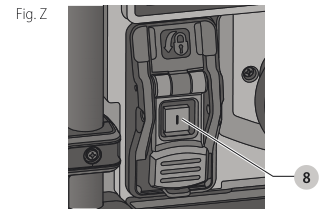

Rail Lock Lever (Fig. BB)

The rail lock lever 9 locks the fence in place preventing movement during cutting. To lock the rail lever, push it down and toward the rear of the saw. To unlock, pull it up and toward the front of the saw.

NOTE: When ripping, always lock the rail lock lever.

Work Support Extension/Narrow Ripping Fence

The table saw is equipped with a narrow ripping fence that also supports work that extends beyond the saw table.

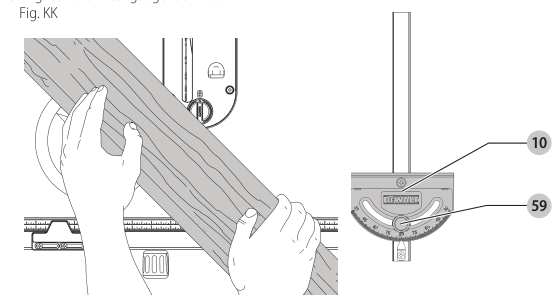

To use the narrow ripping fence in the work support position, rotate it from its stored position as shown in Figure BB, and slide the pins into the lower sets of slots 59 on both ends of the fence. To use the narrow ripping fence in the narrow ripping position, snap the two upper sets of slots 59 on both ends of the fence.

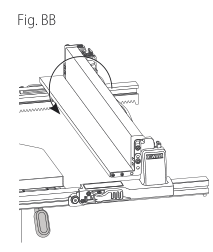

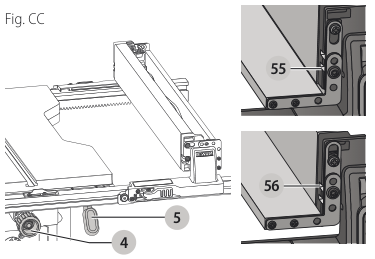

This feature will leave a 1–1/2" (51 mm) of extra clearance to the blade. Refer to Figure CC. If more clearance is necessary, follow directions for making an auxiliary fence under Narrow Rip Auxiliary Fence in the Storage section.

NOTE: When not in use, the narrow ripping fence should be placed in its stored position. NOTE: When using the narrow ripping fence, subtract 2" (51mm) from the indicated rip scale reading.

NOTE: This fence will allow the guard to remain on the saw when completing narrow ripping. This fence will provide ample space for a push stick. If you prefer more clearance for push blocks or push sticks, refer to Narrow Rip Auxiliary Fence.

Fine Adjustment Knob (Fig. CC) The fine adjustment knob allows smaller adjustments when setting the fence. Before adjusting, be sure the rail lock lever is in locked or unlocked position.

Rip Scale Pointer The rip scale pointer will need to be adjusted for proper performance of the rip fence if the user switches between the right and left blades. The rip scale pointer only reads correctly when the fence is installed in position 1 or 2 to the right side of the blade. When using the narrow ripping fence for narrow ripping (not in work support position), subtract 2" (51mm) from the indicated rip scale reading. See Adjusting the Rip Scale under Assembly.

Through-Cutting Operations

WARNING: Use blade guard assembly for all through-cutting operations.

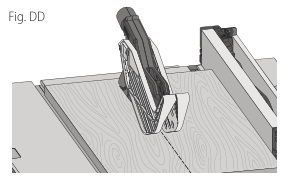

Ripping (Fig. DD)

WARNING: Never touch the “free end” of the workpiece or a “free piece” that is cut off, while the power is ON and/or the saw blade is rotating. Piece may contact the blade resulting in thrown workpiece and possible injury. WARNING: A rip fence should ALWAYS be used for ripping operations to prevent loss of control and personal injury. NEVER perform a ripping operation freehand. ALWAYS lock the fence to the rail. WARNING: When bevel ripping and whenever possible, place the fence on the side of the fence to the end grain. WARNING: When bevel ripping and whenever possible, place the fence on the side of the blade so that the blade is tilted away from the fence and hands. WARNING: Keep hands clear of the blade. WARNING: Use the riving knife for non-thru-sawing when blade guard assembly cannot be used. WARNING: Use a push stick to feed the workpiece if here is 2–6" (51–152 mm) between the fence and the blade. Use a narrower ripping fence feature and push block to fed the workpiece if here is 2" (51 mm) or narrower between the fence and the blade.

- Lock the rip fence by pressing the rail lock lever down. Remove the riving knife gauge.

- Raise the blade so it is about 1/8" (3.2 mm) higher than the top of the workpiece.

- Hold the workpiece flat on the table and against the fence. Keep the workpiece about 1" (25.4 mm) away from the blade.

CAUTION: The workpiece must have a straight edge against the fence and must not be warped, twisted or bowed. Keep both hands away from the blade and away from the path of the blade. See proper hand position in Figure E.

- Turn the saw on and allow the blade to come up to speed. Both hands can be used in starting the cut when the rip approximately 12" (305 mm) left to feed. In use, only one hand to hold and the other holds firmly with hand index and second finger holding the workpiece. Keep your other fingers hooked over the fence. Always keep your thumb along side your first two or three fingers.

- Keeping the workpiece against the table and fence, slowly feed the workpiece rearward and with the power switch saw blade. Continue pushing the workpiece until it is clear of the blade guard assembly and it falls off the rear of the table. Do not overload the motor.

- Never try to pull the workpiece back with the blade turning. Turn the switch off, allow the blade to stop, raise the anti-kickback teeth on each side of the riving knife if necessary and slide the workpiece out.

- When sawing a long piece of material or a panel, always use a work support. A sawhorse, rollers, or out feed assembly provides adequate support for this purpose. The work support must be at the same height or slightly lower than the saw table.

CAUTION: Never push or hold onto the free or cut-off side of the workpiece if it is between the blade and the fence.

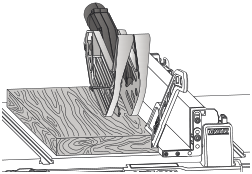

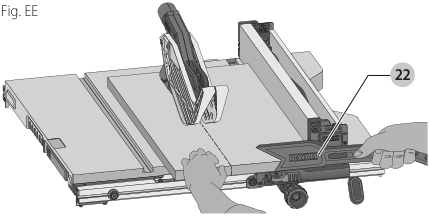

Ripping Small Pieces (Fig. EE)

It is unsafe to rip small pieces. It is not safe to put your hands close to the blade. Instead, rip a larger piece to obtain the desired piece. When a small width is to be ripped and the hand cannot be safely put between the blade and the rip fence, use one or more push sticks. A pattern is included at the end of this manual to make push sticks. A push stick is included with this saw, attached to the rip fence. Use the push stick to hold the workpiece against the table and fence, and push the workpiece fully past the blade.

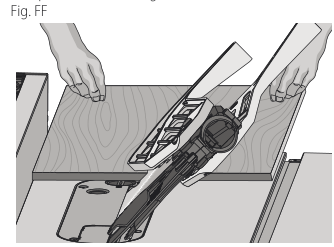

Bevel Ripping (Fig. FF)

This operation is the same as ripping except the bevel angle is set to an angle other than zero degrees. For proper hand position, Refer to Figure FF.

WARNING: Before connecting the table saw to the power source or operating the saw, always inspect the blade guard assembly and riving knife for proper alignment and clearance with saw blade. Check alignment after each change of bevel angle.

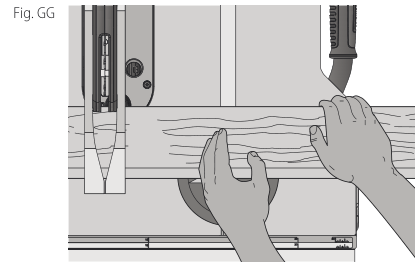

Crosscutting (Fig. GG)

WARNING: NEVER touch the “free end” of the workpiece or a “free piece” that is cut off, while the power is ON and/or the saw blade is rotating. Piece may contact the blade resulting in thrown workpiece and possible injury. WARNING: To reduce the risk of injury, NEVER use the fence as a guide or length stop when crosscutting. WARNING: NEVER use a length stop on the free end of the workpiece when crosscutting. In short, the cut leaves and/or the saw blade is rotating. Piece may contact the workpiece or sparktic must never be confined — it must be able to move away from saw blade to prevent contact with blade resulting in thrown workpiece and possible injury. WARNING: Use another warning stating to eat prevent binding of the blade guard assembly against the workpiece resulting in damage to saw and possible injury. CAUTION: When using a block as a cut-off gauge, the block must be at least 3/4" (19 mm) thick. It there is a possibility of kickback to prevent contact with blade resulting in thrown workpiece and possibly injury.

- Remove the riving knife and store the riving gauge in the desired cut location.

- Adjust the blade height so that the blade is about 1/8" (3.2 mm) higher than the top of the workpiece.

- Hold the workpiece firmly against the miter gauge with the path of the blade in line with the desired cut location. Keep the workpiece an inch or so in front of the blade. KEEP BOTH HANDS AWAY FROM THE BLADE AND THE PATH OF THE BLADE (Fig. GG).

Table saw blade adjustment

Instructions in the Ripping, Crosscutting, Bevel Crosscutting, Mitering, and Compound Mitering sections are for cuts made through the full thickness of the material. The saw can also perform non-through cuts to form grooves or rabbets in the material.

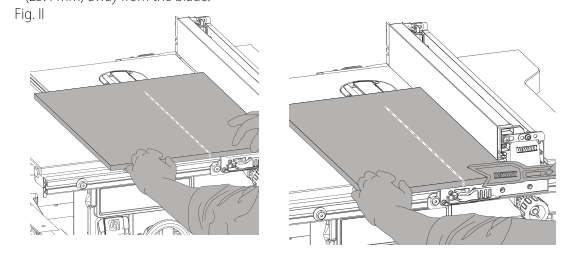

Non-Through-Ripping (Fig. II)

- WARNING: A rip fence should ALWAYS be used for ripping operations to prevent loss of control and personal injury. NEVER perform a ripping operation freehand. ALWAYS lock the fence to the rail.

- WARNING: When bevel ripping and whenever possible, place the fence on the side of the blade so that the blade is tilted away from the fence and hands.

- WARNING: Keep hands clear of the blade. With non-through-cutting the blade is not always visible during the cut, so increased caution is necessary to ensure hands are clear of the blade.

- WARNING: Use a push stick to feed the workpiece if there are 2"–6" (51–152 mm) between the fence and the blade. Use a narrow ripping fence feature and push block to feed the workpiece if there are 2" (51 mm) or narrower between the fence and the blade.

- Remove the blade guard assembly and install the non-through-cutting riving knife (Fig. GG). Refer to "Installing/Removing the Blade Guard Assembly and Riving Knife."

Image showing blade guard removal - Lock the rip fence by pressing the rail lock lever down. Remove the miter gauge.

- Raise the blade to the desired cut depth.

- Hold the workpiece flat on the table and against the fence. Keep the workpiece about 1" (25.4 mm) away from the blade.

Bevel Crosscutting

This operation is the same as crosscutting except that the bevel angle is set to an angle other than 0°.

- WARNING: Before connecting the table saw to the power source or operating the saw, always inspect the blade guard assembly and riving knife for proper alignment and clearance with saw blade. Check alignment after each change of bevel angle.

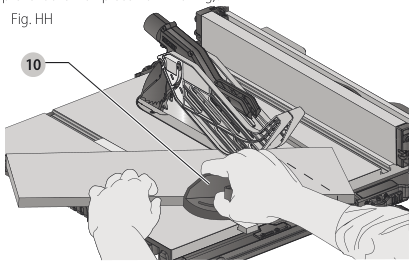

Mitering (Fig. HH)

- WARNING: Miter angles greater than 45° may force the blade guard assembly into the saw blade causing damage to the blade guard assembly and personal injury. Before starting the motor, test the operation by feeding the workpiece into the blade guard assembly. If the blade guard assembly contacts the blade, place the workpiece under the blade guard assembly, not touching the blade, before starting the motor.

- CAUTION: Certain workpiece shapes, such as molding, may not lift the blade guard assembly properly. Feed the workpiece slowly to start the cut. If the blade guard assembly contacts the workpiece, replace it. To start the cut, if the blade guard assembly contacts the workpiece, use the workpiece to lift the blade guard assembly, not touching the blade, before starting the motor.

This operation is the same as crosscutting except the miter gauge is locked at an angle other than 0°. Hold the workpiece FIRMLY against the miter gauge

Miter Gauge Operation

To set your miter gauge:

- Loosen the miter gauge lock knob.

- Move the miter gauge to the desired angle.

- Tighten the miter gauge lock knob.

Compound Mitering

This is a combination of bevel crosscutting and mitering. Follow the instructions for both bevel crosscutting and mitering.

Non-Through-Cutting (Grooving and Rabbeting)

- WARNING: Remove the blade guard assembly and install the non-through-cutting riving knife. Use featherboards for all non-through-cutting operations where the blade guard assembly, anti-kickback assembly, and riving knife cannot be used.

Non-Through-Ripping Small Pieces (Fig. AA)

It is unsafe to rip small pieces. It is not safe to put your hands close to the blade. Instead, rip a larger piece to obtain the desired piece. When a small width is to be ripped and the hand cannot be safely put between the blade and the rip fence, use one or more push sticks. A pattern is included at the end of this manual to make push sticks. A push stick

Non-Through-Bevel Ripping (Fig. JJ)

This operation is the same as non-through-ripping except the bevel angle is set to an angle other than zero degrees. For proper hand position, Refer to Figure JJ.

Non-Through-Crosscutting

- WARNING : NEVER use rip fence in combination with miter gauge.

- WARNING : To reduce the risk of injury, NEVER use the fence as a guide or length stop when crosscutting.

- WARNING : When using a block as a cut-off gauge, the block must be at least 3/4" (19 mm) thick and it is very important that the rear of the block be positioned so the workpiece is clear of the block before it enters the blade to prevent contact with blade resulting in a thrown workpiece and possibly injury.

- Remove the rip fence and place the miter gauge in the desired slot.

- Adjust the blade height to the desired cut depth.

- Hold the workpiece firmly against the miter gauge with the path of the blade in line with the desired cut location. Keep the workpiece an inch or so in front of the blade. KEEP BOTH HANDS AWAY FROM THE BLADE AND THE PATH OF THE BLADE.

- Start the saw motor and allow the blade to come up to speed.

- While using both hands to keep the workpiece against the face of the miter gauge, and holding the workpiece flat against the table, slowly push the workpiece through the blade.

- Never try to pull the workpiece back while the blade turning. Turn the switch off, allow the blade to stop, and carefully slide the workpiece out.

Non-Through-Bevel Crosscutting

This operation is the same as crosscutting except that the bevel angle is set to an angle other than 0º.

- WARNING : Before connecting to power source or operating the saw, always inspect the riving knife for proper alignment and clearance with saw blade. Check alignment after each change of bevel angle.

Non-Through-Mitering (Fig. KK)

This operation is the same as crosscutting except the miter gauge is locked at an angle other than 0º. Hold the workpiece FIRMLY against the miter gauge and feed the workpiece slowly into the blade to prevent stalling the saw.

Non-Through-Miter Gauge Operation

- Loosen the miter gauge lock knob.

- Move the miter gauge to the desired angle.

- Tighten the miter gauge lock knob.

Non-Through-Compound Mitering

This is a combination of non-through-bevel crosscutting and non-through-mitering. Follow the instructions for both non-through-bevel crosscutting and non-through-mitering.

Dado Cutting

- CAUTION : Do not attempt to stack dado blades thicker than 13/16" (20 mm). Do not use dado blades larger than 8" (200 mm) diameter.

Since dados are non-through cuts, the riving knife must be removed with the blade guard assembly removed. Since the dado blade is smaller diameter and thicker than the standard blade, the non-through cutting riving knife also cannot be used. To remove the blade guard assembly or non-through cut riving knife, pull wing knife/blade guard release lever and pull up on the guard or riving knife to remove.

Use EXTREME care when using the dado without the blade guard assembly and riving knife. When using the dado, the special dado insert (also sold as an accessory) must be used. Anytime a cut is required that is considerably wider than the saw kerf, a dado is used. A dado cut is commonly used to add support and line up a shelf or a cabinet, bookcase or some such project. If a deep cut is required, use several successive passes rather than attempting to make it with one pass. Maximum dado width on this saw is 13/16" (20 mm). DO NOT USE WIDER COMBINATIONS.

- CAUTION : Always check dado blade clearance before plugging in the saw.

Be sure to place the blade guard assembly and standard throat plate back in position and check adjustments when the dado cut is complete. Reinstall blade guard assembly, anti-kickback assembly and riving knife.

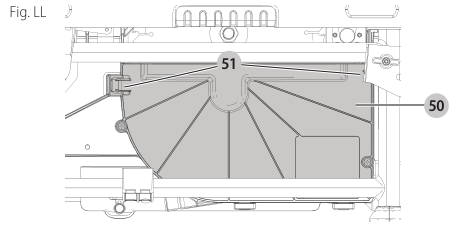

Dust Collection (Fig. A, LL)

This table saw is equipped with dual dust collection port and dust collection port. For best results, connect a vacuum to the port at the rear of the saw and on the guard using a Y connector. The Y connector is available as an accessory at additional cost. Refer to Accessories.

NOTICE : Care should be taken to position hose to not interfere with cutting operation.

After extended use, the saw’s dust collection system may become clogged. To clear the dust collection system:

- Unplug the saw.

- Turn the saw on its side, so the bottom, open part of the unit is accessible.

- Open the dust access door shown in Figure LL by removing the screws and pressing the side clips toward each other. Clean out the excess dust, and re-secure by pushing the side clips completely into place and loose the screw.

Motor Overload and Power Loss Reset Switch

If power is interrupted by a circuit breaker trip, power loss, or other causes, the saw contains a power loss reset switch feature that will automatically reset to OFF position.

Circuit breaker overload is often the result of a dull blade. Change your blade on a regular basis to avoid tripping your breaker. Disconnect the saw from power source and check your blade before re-setting the circuit breaker and continuing to saw.

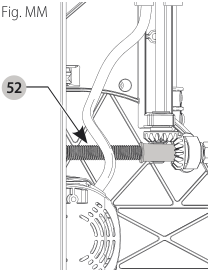

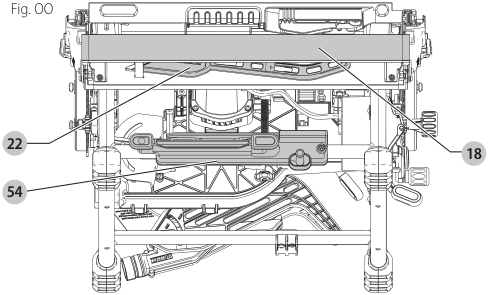

Lubrication (Fig. MM)

- All motor bearings are permanently lubricated at the factory and no additional lubrication is needed.

- The height adjustment screw may require periodic cleaning and lubrication to ensure thread area clear. If you have difficulty raising or lowering the blade: a. Unplug the saw. b. Turn the saw on its side, so the bottom, open part of the unit is accessible. c. Clean and lubricate the height adjustment screw threads on the underside of this saw with general purpose grease. Refer to Figure MM.

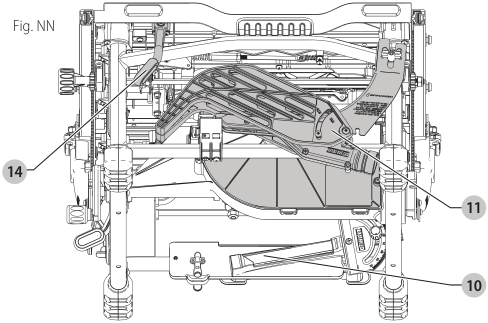

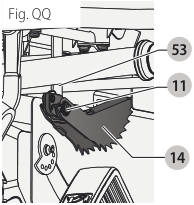

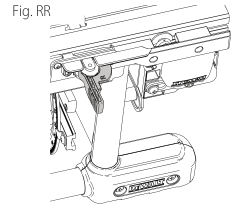

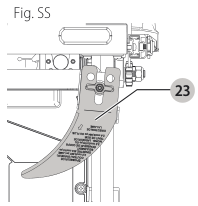

STORAGE (FIG. NN–SS)

- Attach push stick to fence.

- Remove the blade guard assembly. Refer to Remove Blade Guard Assembly. Slide blade guard assembly into holder as shown, then turn lock 1/4 turn to lock in place.

- Depress the stem on the anti-kickback assembly to allow the assembly to slide from the riving knife slot.

Transporting (Fig. A)

WARNING: To reduce the risk of serious personal injury, turn unit off and disconnect it from power source before transporting the saw. An accidental start-up can cause injury.

WARNING: Always transport the machine with the upper blade guard fitted.

- Before transporting, lock the fence in place, lower the blade and lock the bevel.

- Always carry the machine using the carry handles.

Accessory Construction for Alternative Operation Methods

(If not equipped with narrow ripping fence)

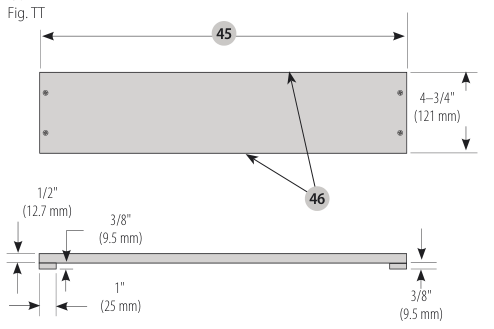

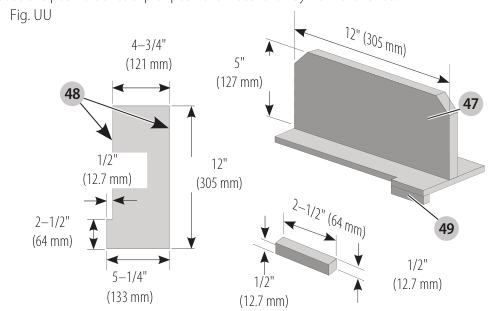

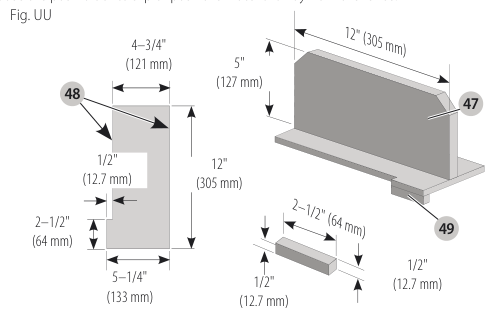

Narrow Rip Auxiliary Fence (Fig. TT, UU)

The narrow rip auxiliary fence should be used for a rip of 2" (51 mm) or narrower. This fence will allow the guard to remain on the saw when completing narrow ripping. This fence will provide ample space for proper use of a push block.

- Follow the diagram in Fig. TT to construct the narrow rip auxiliary fence.

NOTE: The length should be cut to fit the length of the saw table top and sides must be parallel.

- Dimensions:

- Height: 4-3/4" (121 mm)

- Width: 1/2" (12.7 mm)

- Lip: 3/8" (9.5 mm)

- Overhang: 5-1/4" (133 mm)

- After the narrow rip auxiliary fence is constructed, slip it over the saw table top and place it flush to the fence as shown in Figure WW.

- Feed the workpiece through until the edge of the material reaches the front edge of the saw table top.

- Continue feeding the material using the push block until the cut is complete.

Push Block (Fig. UU, WW)

IMPORTANT: Only use the push block with the narrow rip auxiliary fence, refer to Narrow Rip Auxiliary Fence. The push block should be used once the material being cut reaches the saw table top.

- Construct a push block using the diagram in Figure UU.

NOTE: Edges must be the same size.

- Dimensions:

- Length: 12" (305 mm)

- Width: 2-1/2" (64 mm)

- Lip: 1/2" (12.7 mm)

- Place the push block behind the material and ensure the lip of the block is flush to the narrow rip auxiliary fence.

- Once the push block is in place, continue feeding the material until the cut is complete making sure the push block remains flush to the narrow rip auxiliary fence at all times.

IMPORTANT: The narrow rip auxiliary fence and the over hanging edge must both be the same thickness.

Illustrations

-

Anti-kickback assembly and storage -

Zoom on table detail -

Zoom on wrench storage -

Zoom on push block dimensions -

Zoom on auxiliary fence dimensions -

Zoom on blade guard details -

Zoom on saw setup

Featherboard Illustration

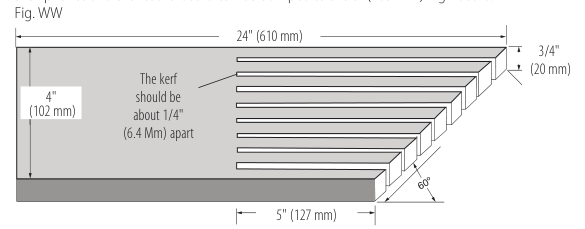

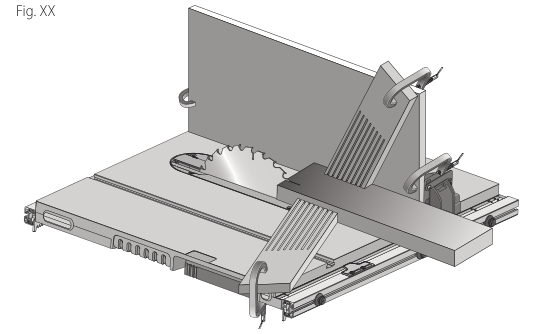

Featherboard Construction (Fig. WW, XX)

Featherboards are used to keep the work in contact with the fence and table, and help prevent kickbacks. Dimensions for making a typical featherboard are shown in Figure WW. Make the featherboard from a straight piece of wood that is free of knots and cracks. Clamp the featherboard to the fence and table so that the leading edge of the featherboard will support the workpiece until the cut is complete (Fig. XX). An 8" (203 mm) high flat board can be clamped to the rip fence and the featherboard can be clamped to the 8" (203 mm) high board.

- WARNING: Use featherboards for all non thru-sawing operations where the blade guard assembly, anti-kickback assembly and riving knife cannot be used. Always replace the blade guard assembly, anti-kickback assembly and riving knife when the non-thru sawing operation is complete. Make sure the featherboard presses only on the portion of the workpiece in front of the blade.

Maintenance

- WARNING: To reduce the risk of serious personal injury, turn unit off and disconnect it from power source before making any adjustments or removing/installing attachments or accessories. An accidental start-up can cause injury.

Cleaning

- WARNING: Blow dirt and dust out of all air vents with clean, dry air at least once a week. To minimize the risk of eye injury, always wear ANSI Z87.1 approved eye protection when performing this.

- WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts of the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse any part of the tool in a liquid.

Accessories

- WARNING: Since accessories, other than those offered by DEWALT, have not been tested with this product, use of such accessories with this tool could be hazardous. To reduce the risk of injury, only DEWALT recommended accessories should be used with this product. Recommended accessories for use with your tool are available at extra cost from your local dealer or authorized service center. If you need assistance in locating any accessory, please contact DEWALT Industrial Tool Co., 701 East Joppa Road, Towson, MD 21286, call 1-800-4-DEWALT (1-800-433-9258) or visit our website www.dewalt.com.

- DW7440D0 Dado Throat Plate

- DWE7402DI Diastole Detector

- DW7670 Stacked Dado Set

- DWE74911 Rolling Table Saw Stand

- DWAE7921 Scissor Leg Stand

Repairs

- WARNING: To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments (including brush inspection and replacement, when applicable) should be performed by a DEWALT factory service center or a DEWALT authorized service center. Always use identical replacement parts.

Register Online

Thank you for your purchase. Register your product now for:

- WARRANTY SERVICE: Registering your product will help you obtain more efficient warranty service in case there is a problem with your product.

- CONFIRMATION OF OWNERSHIP: In case of an insurance loss, such as fire, flood or theft, your registration of ownership will serve as proof of purchase.

- FOR YOUR SAFETY: Registering your product will allow us to contact you in the unlikely event a safety notification is required under the Federal Consumer Safety Act. Register online at www.dewalt.com/register.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three years from the date of purchase. This warranty does not cover part failure due to normal wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit www.dewalt.com or call 1-800-4 DEWALT (1-800-433-9258). This warranty does not apply to accessories or damage caused where repairs have been made or attempted by others. THIS LIMITED WARRANTY IS GIVEN IN LIEU OF ALL OTHERS, INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, AND EXCLUDES ALL INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or consequential damages, so these limitations may not apply to you. This warranty gives you specific legal rights and you may have other rights which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

- 1 YEAR FREE SERVICE: DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any time during the first year after purchase.

- 90 DAY MONEY BACK GUARANTEE: If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt for a full refund – no questions asked. LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America, see country specific warranty information contained in the packaging, call the local company or see website for warranty information. FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing, call 1-800-4-DEWALT (1-800-433-9258) for a free replacement.